Why is packaging important for your product?

- Almost one-third of product decision-making is based on packaging alone

- More than 70% of the purchasing decisions are made inside the store

- 66% of consumers said they had tried a new product because of the packaging.

- 52% of online shoppers say that they would shop again from the same company if it included some kind of premium packaging

- Businesses have reported a 30% increase in consumer interest when they show strong attention to packaging.

The way you design, produce, and package consumer goods contributes to your success in the market. However, traditional design and prototyping processes are costly and time-consuming. Competitive edge over competitors is a crucial factor for any company, and they spend billions and billions and billions for this advantage. Because of this, 3D printing for packaging and especially into the consumer goods industry has increased in popularity. Companies are quickly learning that 3D printing will allow them to produce more accurate prototypes faster and cheaper.

Advantages:

1. Saves Time – 3D printing makes it possible to produce prototypes much faster than traditional manufacturing techniques, like CNC.

2. Saves Money – Fewer time results in less money expenditure, and a perfect design gives less sunk cost to the company instead of wasting money in trial and error

3. Unimaginable Prototypes – Highly detailed, accurate to micro levels, and smooth scale models printed by 3D printing technology is often used to showcase design ideas. These models also help in situations where CAD models are not sufficient for identifying design issues.

4. Ergonomic Design – Ergonomics aims to make the design of the packaging with human limitations. It is a hands-down winner. 3D printing allows you to apply ergonomic principles to packaging design.

5. Design that Sells – New advancements in 3D printing technology allow companies to work faster, create more effective prototypes, and test packaging designs that grab consumers’ interest and establish brand identity.

6. Mass Customization – 3D printing technology will enable faster manufacturing in a quicker time and mass customization at a moment’s notice

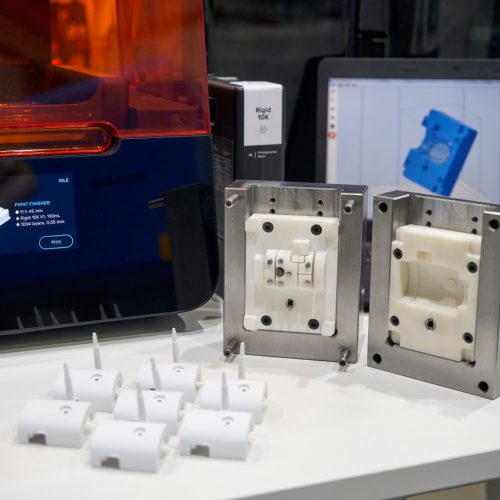

7. Tools Manufacturing – The production of tools and injection moulds can also benefit from 3D printing. As per EY, thirty-nine percent of consumer products companies sees the value of 3D-printed tools in enhancing traditional manufacturing,

8. Sustainability – 3D printing can significantly reduce material waste, thereby making the manufacturing process more sustainable.

Use Cases:

Toly:

Development times for these high-end packages have been significantly reduced at Toly. ” By 3D printing our prototypes in-house, they were saving months versus sending them to get CNC’d. Every CNC prototype took up to 3 weeks, and they also needed multiple iterations, increasing the timings very high. The third-party outsourced models cost 100 euros each to produce. However, to 3D print, an in-house model cost about 25 euros only. Now they were able to 3D print prototypes overnight and test them the very next day. They are creating 100 new product designs each year and are literally saving 10,000s of euros annually with 3D printing technology.