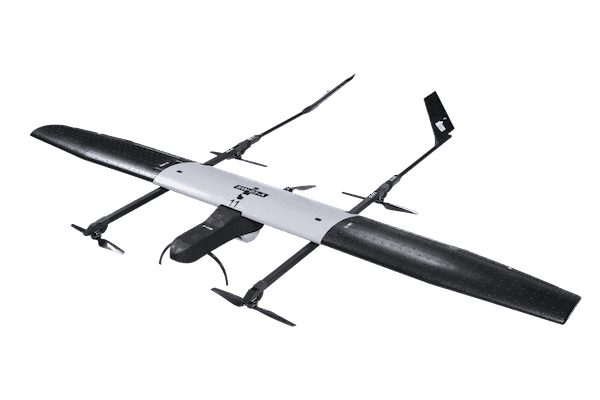

How is 3D printing transforming Drones?

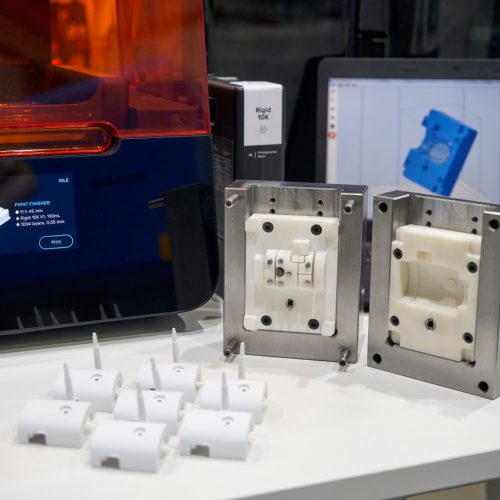

The additive manufacturing industry has made significant progress, meaning that any user with a 3D printer can create their custom drone. The advantage of using additive manufacturing to develop drones is that almost every part of the assembly can be 3D printed, except for the electronic components. In addition to the main elements, many other accessories such as boosters, mounts, or coverings and cases for proper storage of the drones can also be created.

What are the benefits of using 3D Printing for Drone Manufacturing

The 3D printing industry allows you to create your Drone; it’s a perfect way to get a customized drone as per your needs. It costs you less, and the product development process is faster with additive manufacturing technology. It is possible to create lightweight drones, different size drones, and even faster ones.

Create lightweight parts – The parts manufactured via 3D printing is light with excellent strength. These are the two prominent factors needed for drones.

Complex design and assembly – Any intricate design and body can be easily 3D printed, making it very easy to test new designs and variants.

Maintenance management, spare parts – Any maintenance and spare parts can be manufactured with a click of a button by 3D printing technology and different materials.

Mass-customization – 3D printing is the technology that will enable faster manufacturing in a quicker time and mass customization at a moment’s notice

Optimize your parts by rethinking your design – Highly detailed, accurate to micro levels, and smooth scale models printed by 3D printing technology is often used to showcase design ideas. These models also help in situations where CAD models are not sufficient for identifying design issues.

Access perfectly adapted materials – 3D printing allows you to create a broad range of styles that can be further customized to your customers’ requirements

Customized Drones – 3D printing has enabled you to manufacture personalized drones according to your needs and requirements. This increases the feasibility of making customized drones. Any specific part of a store-bought drone can also be tailored to suit your needs.

Easy Upgradation – 3D printing supports the up-gradation of the Drone’s parts to make it more efficient. Design iterations are very economical with this 3D printing technology as compared to the traditional manufacturing processes. This brings in the scope of making many modifications in the 3D design, 3D Printing them, and testing the 3D Printed parts till the desired result is achieved. Flexibility and speed do not stand in the way of the experiment.

Improved Performance – The weight of a drone affects its flight time. The lighter the Drone is, the longer it flies. A lightweight drone has improved battery life, is more responsive and agile during flight. The parts of the Drone are made lighter by optimizing the design structures and maintaining aerodynamics. The choice of material used for 3D printing also plays an essential role in making the parts light, and the designer has the flexibility to try different materials in the prototype stage.

What parts of the Drone can be 3D Printed?

Almost everything in a drone can be 3D Printed (apart from the electronic components).

Following is the list of a few pieces that we can think of right now:

– Frame

– Landing gear

– Propellers

– Camera mount

– Antenna holder

– Protective equipment like prop guards

– And almost everything…

Companies using 3D printing for manufacturing drones

Blue Robotics: This Southern California based Company adopted 3D Printing for developing their submarine drones. The 3D printing technology was used for prototyping and manufacturing certain parts of their Drone at a low cost with utmost quality. This helped them test their designs in a shorter time. They didn’t have to order parts in bulk to save the price, which usually happens in other manufacturing processes like casting, injection molding. With 3D designing and 3D printing, the company made a unique revolutionary product that allowed their underwater Drone to operate even when submerged in saltwater fully.