Elegance meets Power

Volterra brings together some of the most powerful features of thermoplastic 3D Printing in a neat, easy to understand and user friendly package that ensures you meet the most demanding of applications and ensuring your success.

Swipe to interact

Printer Architecture

- Sturdy Sheet-Metal Construction with Integrated Storage Solution for Material and Tools.

- Heated Filament Chamber, compatible with 3KG Filament Spools.

- Heated Build Envelope.

- 7-inch capacitive touch HMI.

- Industrial Safety: Integrated Emergency Stop, Tower Light, Switchgear & HEPA Filter.

- IOT enabled Monitoring & Control

- IMEX Retracting Tool Heads.

- Replaceable & Interchangeable Tools.

- Large Build Volume

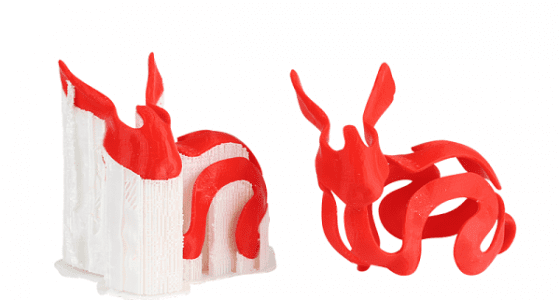

Complete Freedom of Complexity

Volterra’s IMEX Retracting Nozzle System with Water Soluble Supports enable you to go beyond what is possible with 3D printing, allowing you to print extremely complex geometries.

Repeatable. Reliable. Flawless.

Industrial Kinematics with THK rails maximizes printing speed while maintaining incredible precision.

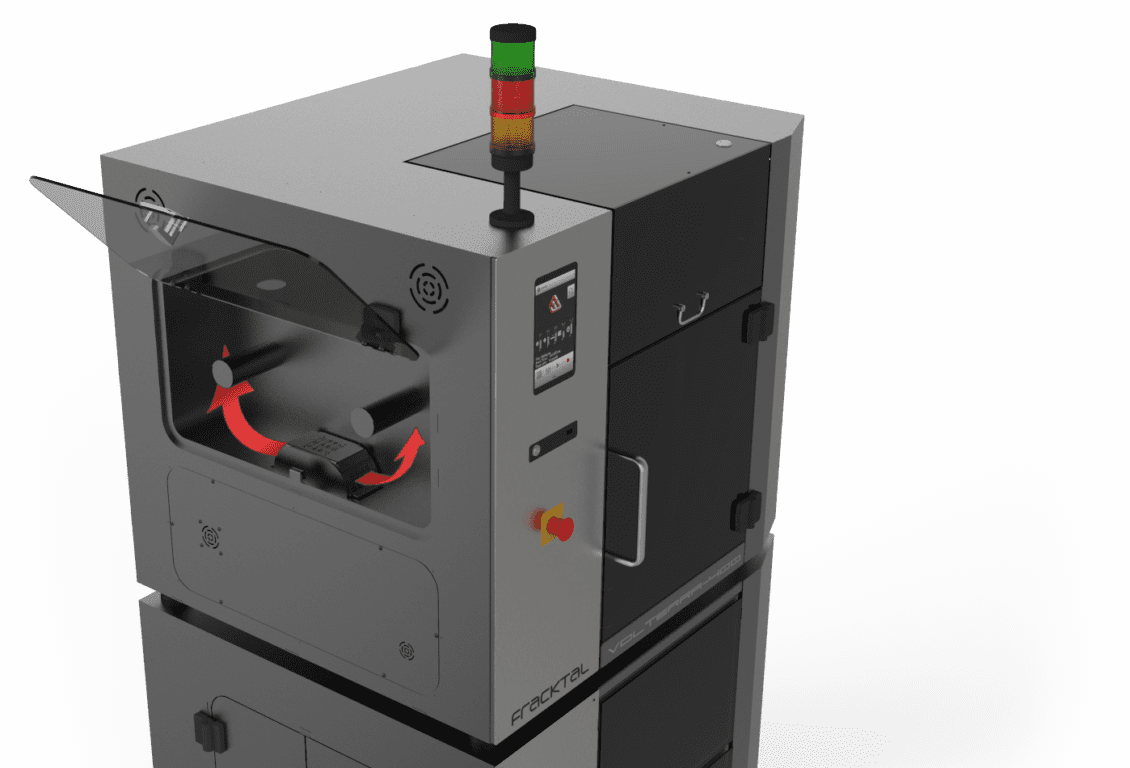

Integrated Heated Filament Chamber

Moisture is the enemy while printing Industrial Thermoplastics, severely affecting printing performance.

Volterra’s heated filament chamber keeps moisture out of Hygroscopic Materials like Polycarbonate, Nylon, PVA, BVOH, PEEK, ULTEM and PEAK.

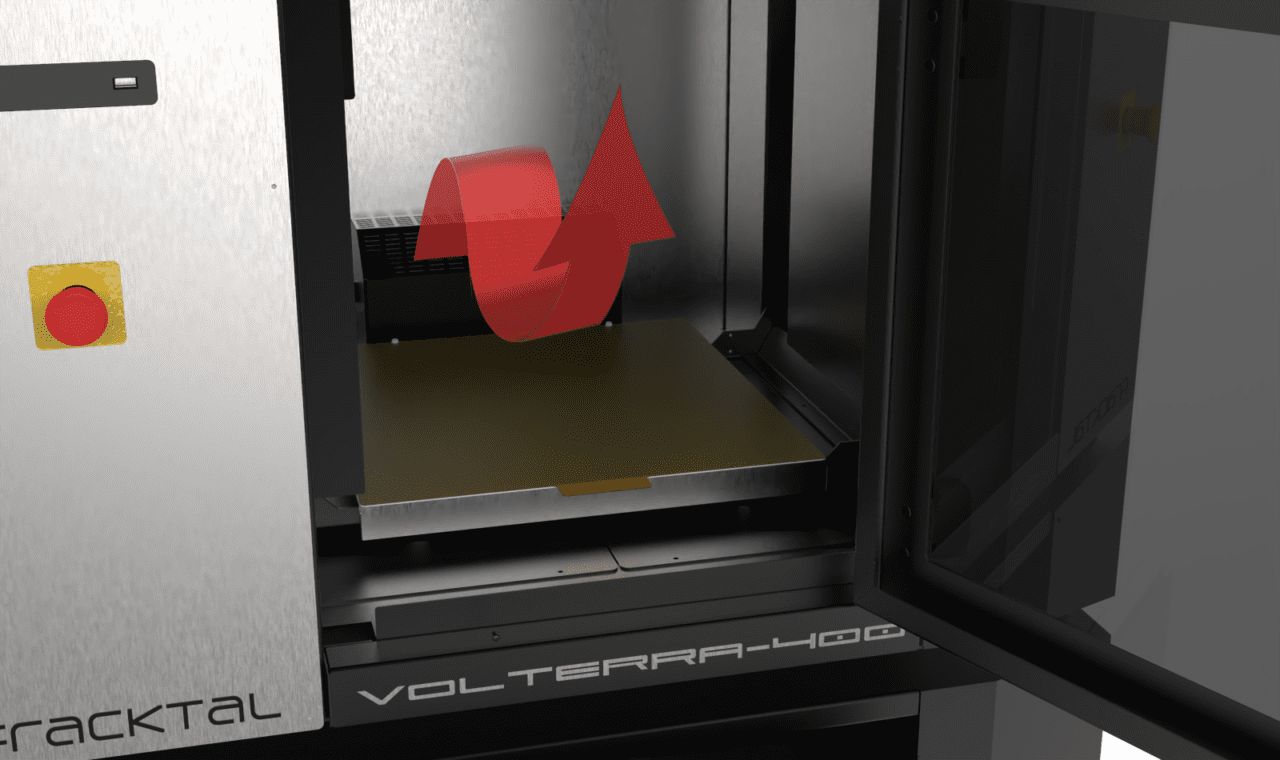

Heated Build Chamber

The inclusion of an enclosed chamber heated by a 100W PTC heater ensures reliability when printing performance industrial thermoplastics.

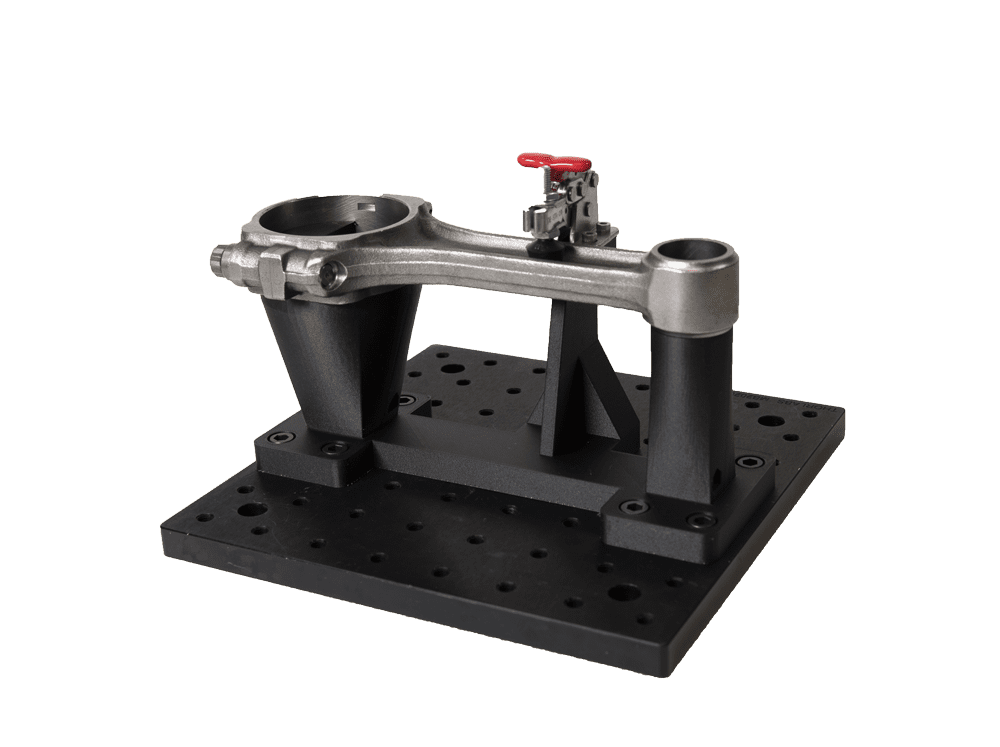

Carbon Fiber Ready

Print strong rigid parts with Carbon Fiber infused Nylon 12 that can be used for Jigs, Fixtures and End-Use parts in Aerospace, Automotive and other Industries.

Nylon 12 CF Printed CMM Fixture

Nylon 12 CF Printed Drill Guide with Metal Inserts

Industrial Applications

Volterra is being used by a variety of industries in innovative ways, bringing immense value to customers.

Built for the Factory of the Future

Integrating Volterra into your production workflow for jigs & fixtures, spare part production and even end-use parts can have monumental impact in cost and time saving. Find out how we can work with you to make this a reality.

Specifications

Machine Size | 650 mm x 700 mm x 1200 mm (L x B x H) |

Build Volume | 400 mm x 400 mm x 400 mm (L x B x H) |

Print Technology | FFF |

Filament Diameter | 1.75 mm |

Nozzle Diameter | 0.25 mm to 1.2 mm |

Weight | 68 KG |

Number of Nozzles | 2 |

Dual Nozzle System | IMEX Nozzle Retracting System |

Nozzle Materials | Brass, Stainless Steel, Hardened Steel |

Layer Resolution | 0.4 mm nozzle: 100 – 300 micron 0.6 mm nozzle: 150 – 450 micron 0.8 mm nozzle: 200 – 600 micron 1.2 mm nozzle: 300 – 800 micron |

XYZ Resolution | 8 Micron, 8 Micron, 2 Micron |

Display | 7″ inch Capacitve Touch Panel |

Nozzle Replacement | Quick Swap-able Nozzles |

Feeder Type | Direct Drive |

Calibration | Active Automatic Leveling & Calibration |

Build Speed | Upto 75 mm³/s |

Nozzle Temperatures | Upto 450 °C |

Build Plate | PEI Flexbuild Surface For all other materials Nylon Surface For Nylon, Nylon CF |

Build Plate Temperature | Upto 150 °C |

Chamber Temperature | Upto 90 °C |

Operating Temperature | 15°C to 35°C Recommended |

Compatible Materials | ABS, PLA, Tough PLA, PLA+, PETg, PVA, PVA+, BVOH, Polycarbonate, Nylon 12, Carbon Fiber Nylon, Carbon Fiber PLA, PEEK, ULTEM |

Supplied Slicing Software | Fracktory Desktop Slicer |

Supported File Types | STL, OBJ, X3D, 3MF, PNG, JPG |

File Transfer | USB, WIFI, LAN |

Connectivity | USB, WIFI, LAN |

Server | Built in Linux based Server running Octoprint |

Training | Online or Onsite training & Installation options available |

Warranty Period | 12 Months |

Expert Support | E-mail, phone, and live-operating via Anydesk |