The blend gives ABS its strength, toughness, and heat resistance, making it ideal for creating functional and mechanical parts.

It also allows for easy post-processing like sanding and acetone smoothing, making it a versatile choice for prototypes and end-use products.

PLA offers easy printability, eco-friendly composition, and cost-effective performance for high-quality visual prototypes and educational models.

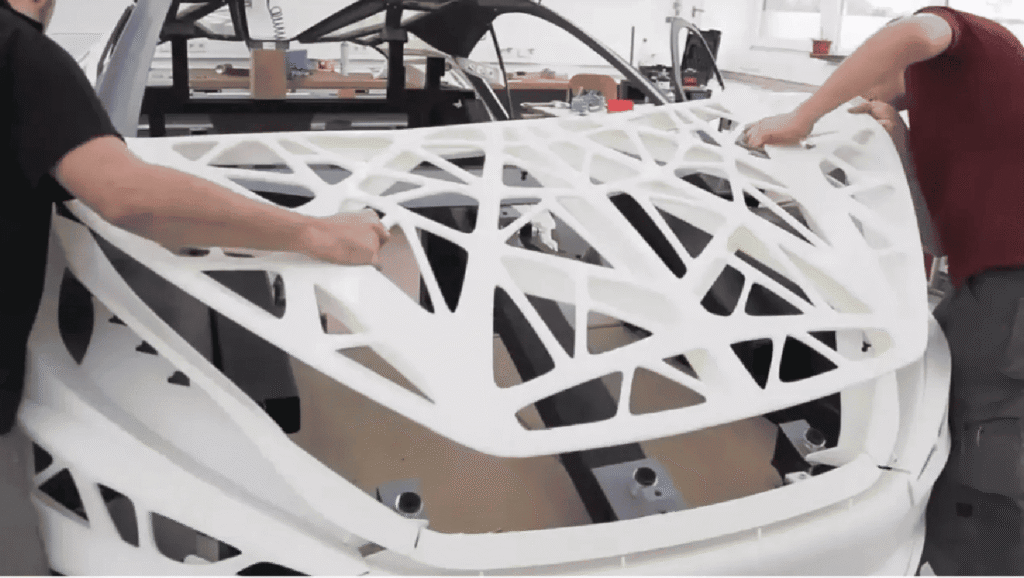

ABS stands out as the engineering-grade choice for functional 3D printing applications. With perfect scores in both strength and durability, this thermoplastic excels where PLA falls short – in demanding mechanical applications and outdoor environments.

Ideal Applications:

Trade-offs: While ABS offers superior mechanical properties, it requires more expertise to print successfully. The material demands higher temperatures, proper ventilation, and a heated bed to prevent warping. The slightly higher cost is offset by its exceptional durability and professional-grade results.

Overall Score: 3.7/5 – A robust material for users prioritizing strength and longevity over ease of use.