All in one solution for your filament moisture control

State-of-the-art filament moisture control solution

Innovative in-line design ensures only the necessary section is dried, saving time and energy

Smart sensors guarantee optimal filament conditions, preventing damage

Intuitive interface and exchangeable cartridges make operation effortless

Intelligent monitoring protects your filament and ensures reliable performance

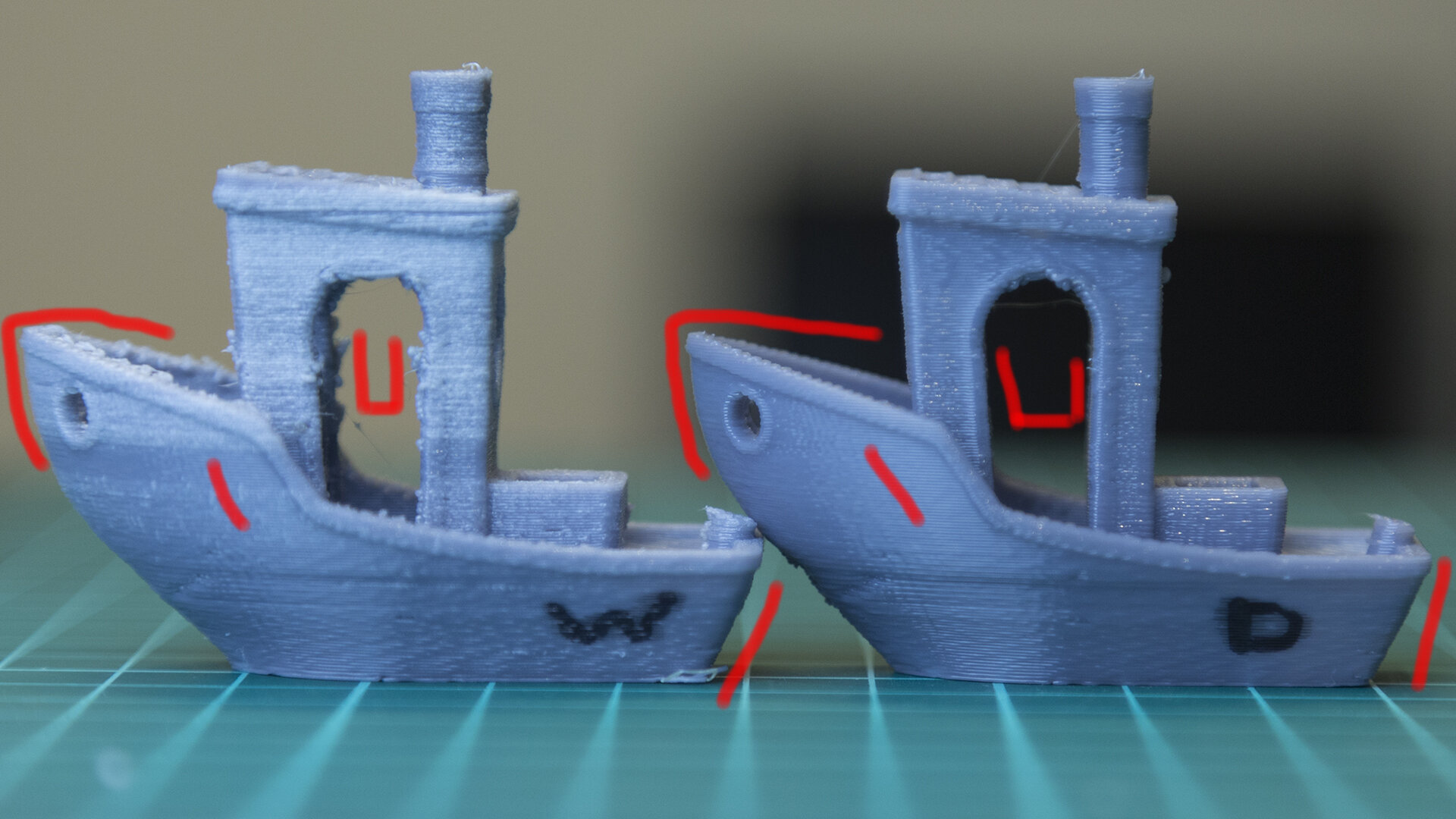

3D printing filaments are hygroscopic, absorbing water from the atmosphere, and therefore need drying to perform at their best. In injection molding it is common practice to dry the material filament before use and most 3D printing filament is composed of the same base resins..

3D printing filaments are hygroscopic, absorbing water from the atmosphere, and therefore need drying to perform at their best. In injection molding it is common practice to dry the material filament before use and most 3D printing filament is composed of the same base resins.

In some materials, even small amounts of moisture can compromise an entire print. Our data shows, that even new filament – just opened from a sealed box – often needs to be dried for best performance.

Fracktal works

Smart sensors help to dry the filament to the best 3D printing condition, avoiding any damage to the filament. The in-line design also avoids multiple heat cycles.

Any spool format or size can be used with Drywise thanks to the in-line architecture. Drywise is available in 1.75 or 2.85mm versions

hOW iT wORKS

Efficient drying reduces processing time, accelerating production.

Prevent material waste from moisture-related print failures.

Minimize filament usage by reducing re-prints

Dry the filament as and when required by the machine

Automatic drying parameters and filament feed-in reduces drying time

Eliminate post-processing efforts and avoid costly re-prints

Pre-configured drying parameters for all commonly used filaments

Valuable time is lost planning material drying, researching the correct drying parameters and handling material.

The filament needs to be optimally dried before printing. This takes many hours (even days) depending on the state of the material. This could delay scheduled production.

Full utilisation of the machinery at hand is very difficult as filament needs to be planned and dried days in advance.

Even when following standard operating procedures, different results can be expected. There are many unknowns that affect the process, initial humidity in the filament, relative humidity of the environment, rate of moisture loss in the oven, etc…

After drying, other devices are needed to keep the filament in a good state.

Multiple heat cycles, needed over the course of a spool if this is not used up immediately, eventually degrade the material quality.

Our filament dryer is compatible with a wide range of filament types, including PLA, ABS, PETG, Nylon, and TPU. It can be used for most hygroscopic FDM materials

Our dryer utilizes precise temperature control, efficient air circulation, an optimized drying chamber, and a timer function to ensure even moisture removal.

Yes, up to 3 1kg Spools

Absolutely, Intuitive interface and exchangeable cartridges make operation effortless

Yes, Innovative in-line design ensures only the necessary section is dried, saving time and energy