We all know that there could be multiple industry necessities for 3D Printing. With customized tooling variants, 3D Printing can be highly useful to your enterprise. Robotics can’t be away from this; that is why the robotics industry and additive manufacturing goes hand in hand.

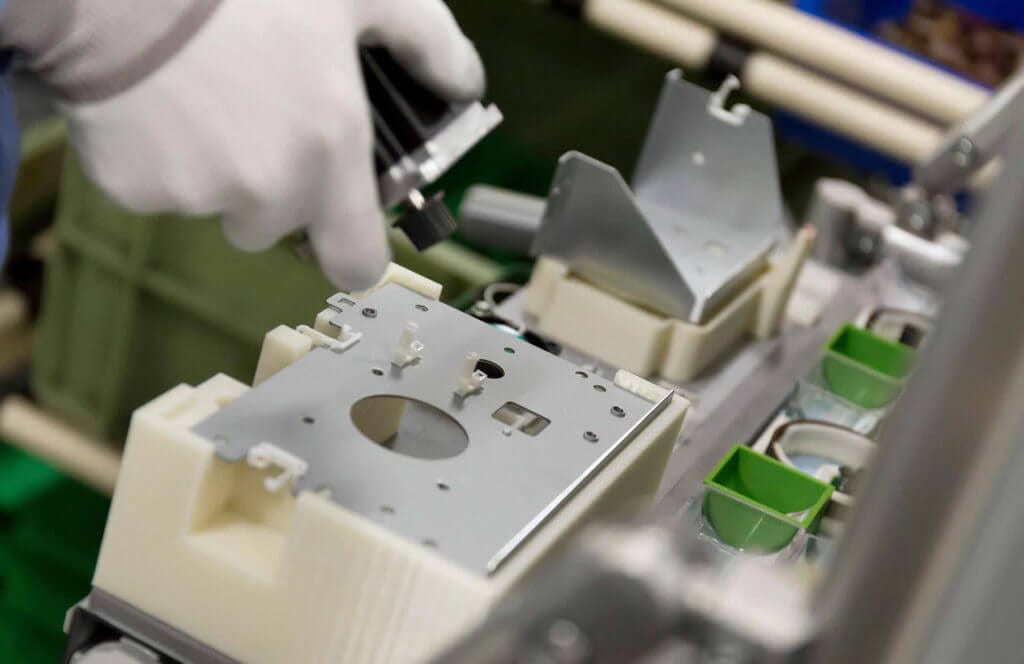

Additive production techniques like 3D Printing facilitate prototyping, tooling, manufacturing, which lowers costs and time to market and helps robotics engineers accomplish their targets & goals. 3D Printing can help you customize designs for robotic applications according to your requirements and optimize the design. Throughout a swarm of markets, additive processing has unique benefits.

Advantages of 3D Printing in the Robotics Industry:

1. Saves Time – 3D Printing makes it possible to produce prototypes much faster than traditional manufacturing techniques, like CNC.

2. Saves Money – Quick time results in less money expenditure, and a perfect design gives the less sunk cost to the company instead of wasting money in trial and error

3. Unimaginable Prototypes – Highly detailed, accurate to micro levels, and smooth scale models printed by 3D printing technology is often used to showcase design ideas. These models also help in situations where CAD models are not sufficient for identifying design issues.

4. Ergonomic Design – Ergonomics aims to make the design of the packaging with human limitations. It is a hands-down winner. 3D Printing allows you to apply ergonomic principles to packaging design.

5. Design that Sells – New advancements in 3D printing technology allow companies to work faster, create more effective prototypes, and test packaging designs that grab consumers’ interest and establish brand identity.

6. Mass Customization – 3D printing technology will enable faster manufacturing in a quicker time and mass customization at a moment’s notice

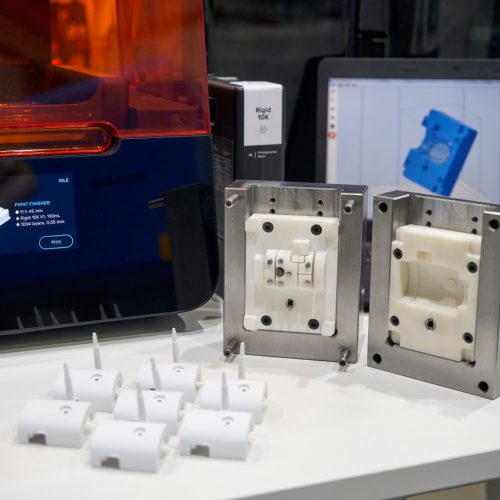

7. Tools Manufacturing – The production of tools and injection molds can also benefit from 3D Printing. As per EY, thirty-nine percent of consumer products companies sees the value of 3D-printed tools in enhancing traditional manufacturing,

8. Sustainability – 3D Printing can significantly reduce material waste, thereby making the manufacturing process more sustainable.

Application of 3D Printing in Robotics Industry:

InMoov: