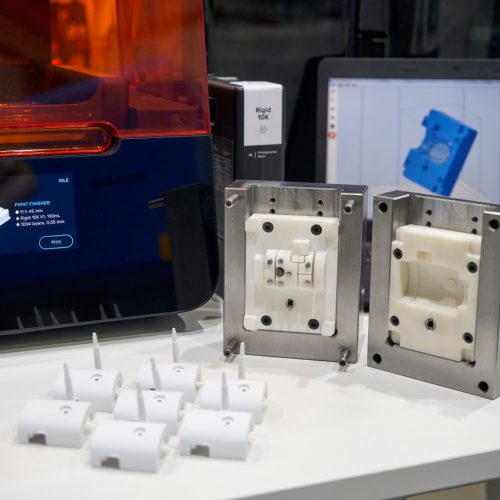

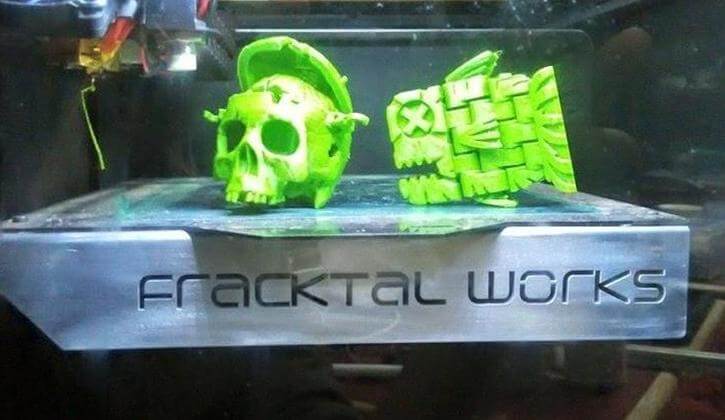

If you’re captivated by the possibilities of 3-D printing, you’re certainly not alone. Manufacturers, engineers, and tech-savvy consumers are using additive manufacturing to create everything from toys to prosthetics and even food. However, the size and functionality of goods they can develop using traditional 3-D printers with plastic and liquid materials is limited.

How it works

While more common 3-D printers use nozzles to squirt liquid into specific shapes, laser additive manufacturing can form parts out of metal. Additive machines use laser beams to fuse together fine layers of powdered metal, ranging from titanium to aluminum and beyond.

This method opens the door for users to develop larger, higher-wear components and parts — at lower costs. It’s particularly beneficial for those in the aviation industry, where insiders have been increasingly reliant on additive manufacturing methods to streamline the machine tooling process of their traditionally complex parts.

Additive manufacturing in action

Additive manufacturing (AM), also known as 3D printing, is a transformative approach to industrial production that enables the creation of lighter, stronger parts and systems. It is yet, another technological advancement made possible by the transition from analog to digital processes.