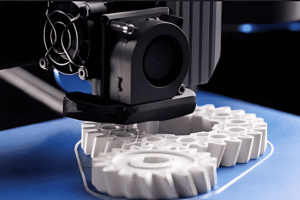

Fracktal Works empowers manufacturing teams to design and produce custom jigs, fixtures, and assembly tools using 3D printing. Our solutions eliminate long lead times, reduce costs, and bring agility to your shop floor. From inspection gauges to ergonomic workholding tools — get the exact fixture you need, exactly when you need it.

Ensure precise positioning of components during manual or semi-automated assembly tasks, reducing errors and increasing repeatability.

Hold parts in a fixed orientation during quality checks or CMM inspection, improving dimensional accuracy and consistency.

Guide tools accurately for drilling or tapping holes, eliminating misalignment and ensuring repeatable hole placement.

Print custom lightweight grippers or holders that attach to robotic arms for handling unique part geometries.

Keep parts securely aligned during welding operations, with options for heat-resistant or semi-rigid materials.

Provide custom hand tools, locator pins, and fixtures designed for operator comfort and reduced fatigue.

Faster Lead Times

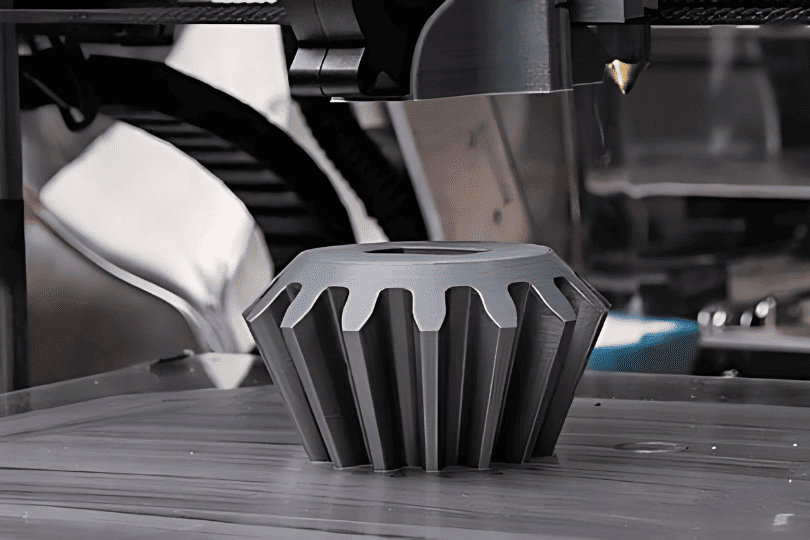

Print jigs and fixtures in a matter of hours or days, rather than waiting weeks for machined tools.

Lower Tooling Costs

Reduce reliance on expensive CNC machining by printing durable tools in-house.

Design Flexibility

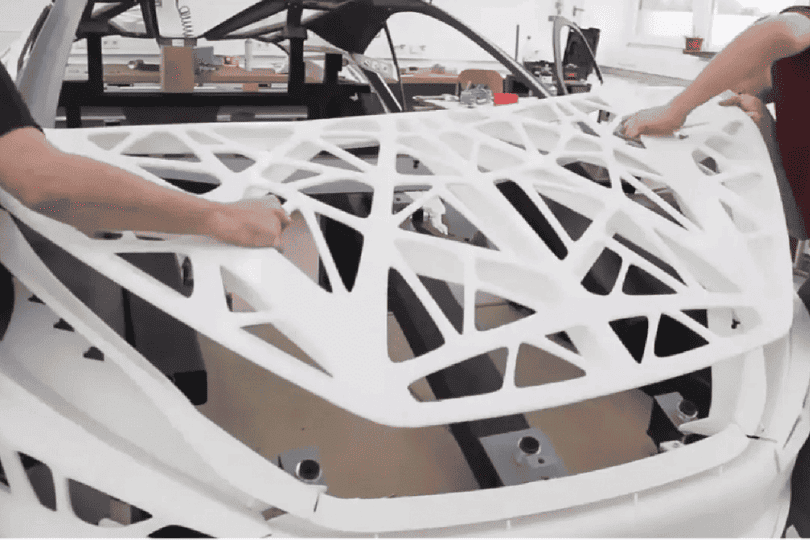

Easily incorporate features like part alignment, weight reduction, or ergonomic grips that are difficult to machine.

Lightweight & Ergonomic

3D printed fixtures can be optimized for weight and form, improving usability and reducing operator fatigue.

Rapid Iteration

Quickly update and reprint tooling as product designs evolve or assembly processes change.

Custom Fit for Every Job

Tailor jigs and fixtures to match exact component geometries for higher precision and lower assembly defects.

Material Constraints

3D printed fixtures may not match the strength or heat resistance of machined metal tools in high-load or high-temperature environments.

Surface Wear

Prolonged use under mechanical stress may lead to wear, requiring periodic replacement or reinforcement.

Tolerance Accuracy

While sufficient for most tooling applications, ultra-high precision requirements may still require CNC-machined parts.

Post-Processing Requirements

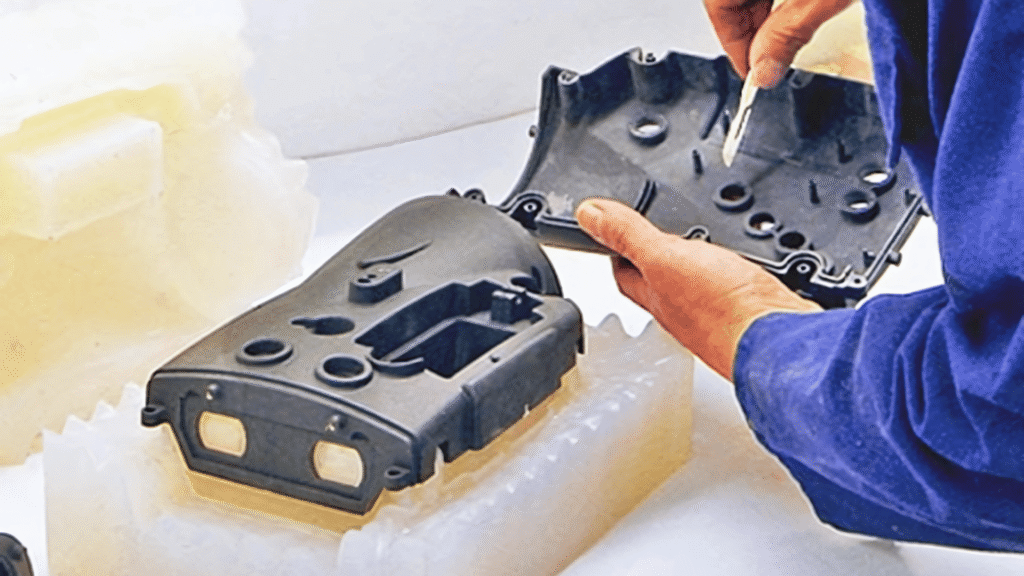

Some fixtures may require support removal, sanding, or inserts to be fully functional on the production line.

Build Volume Limitations

Very large jigs or fixtures may require segmentation and post-print assembly, depending on the printer’s size.

Load-Bearing Capacity

Not all 3D printed materials are suitable for heavy-duty clamping or high-stress environments without reinforcement.

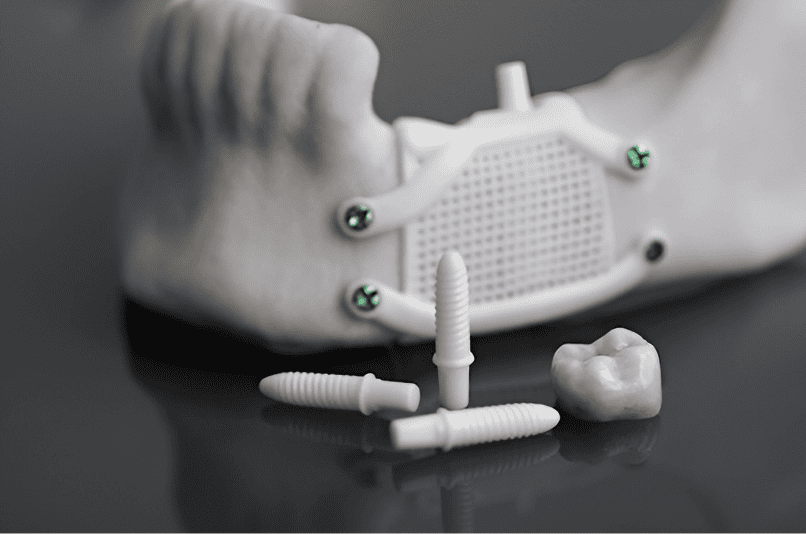

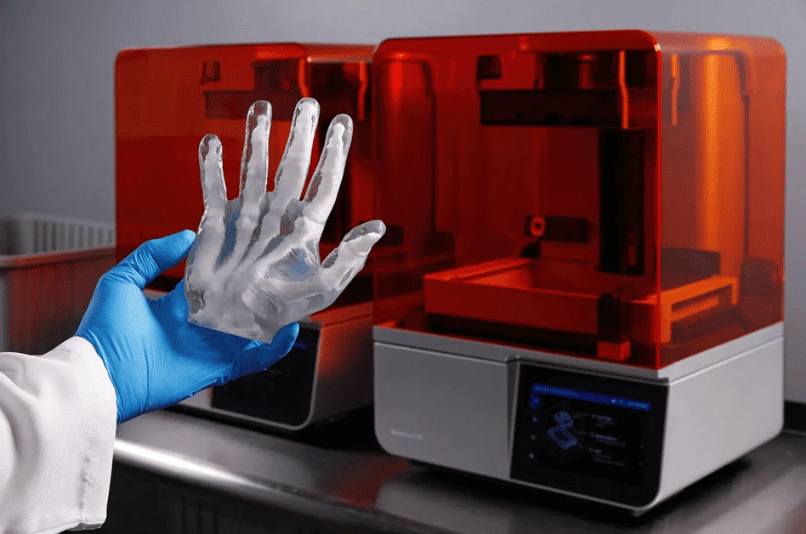

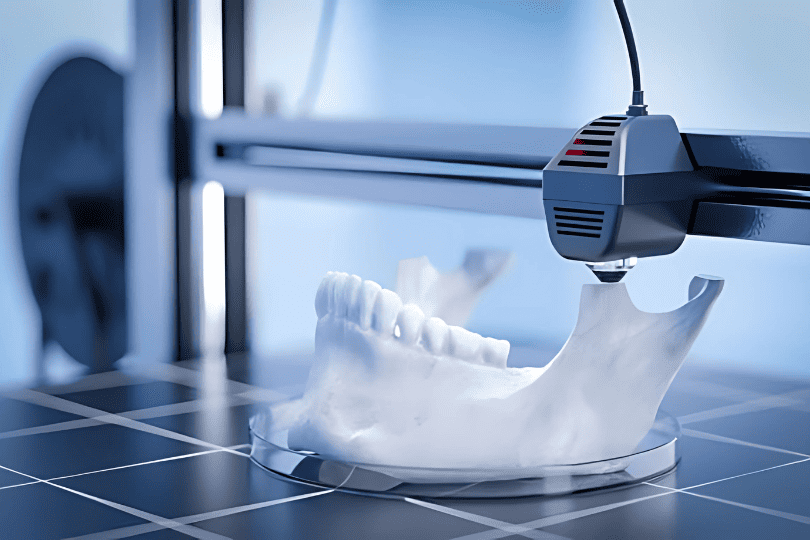

Used in the medical and dental fields to produce short-run parts and functional models with production-like quality.

Used to create prototype parts, interior components, and test-fit parts with materials similar to production plastics.

Occasionally used for making multiple resin-based prototypes or molds for casting final pieces.

Widely used for low-volume production, testing market-ready prototypes, or replacing injection molding in early stages

Used for making durable props or costume components that need to replicate specific designs repeatedly.

Ideal for testing functional parts in small batches before committing to full-scale production.

© 2025 Fracktal Works Pvt. Ltd