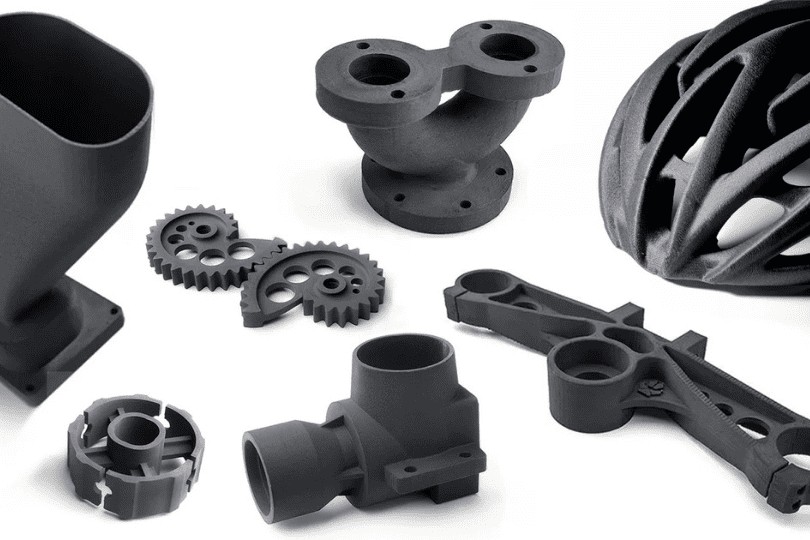

Rapid prototyping using 3D printing enables design teams and engineers to accelerate product development, test fit and function, and reduce costs — all without compromising on quality or performance. With Fracktal Works’ additive manufacturing solutions, you can transform your digital designs into functional prototypes within hours.

Quickly bring design ideas to life with physical models. These prototypes help teams communicate and evaluate early concepts internally or with stakeholders before detailed CAD work or production decisions are made.

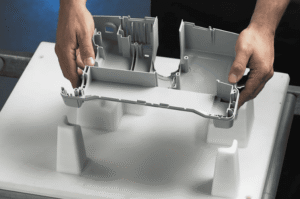

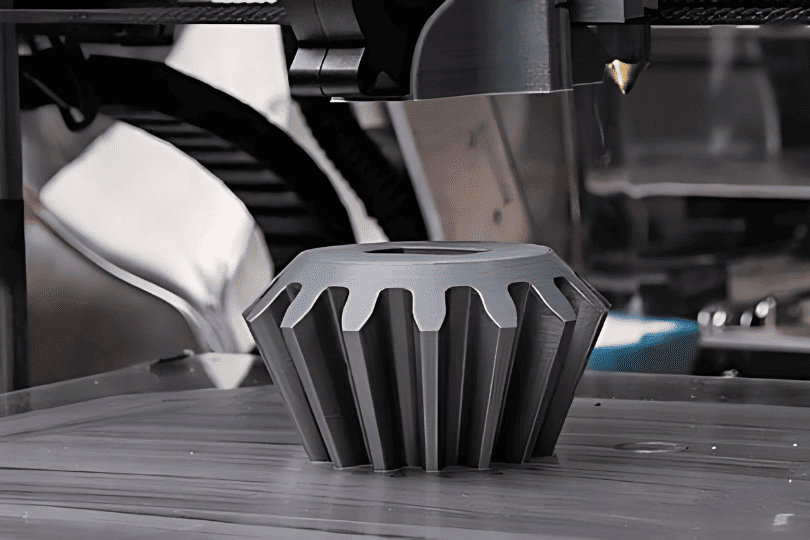

Produce highly accurate prototypes that replicate the final dimensions of the part. These are essential for verifying tolerances, mating surfaces, and assembly compatibility, especially when integrating with other mechanical components.

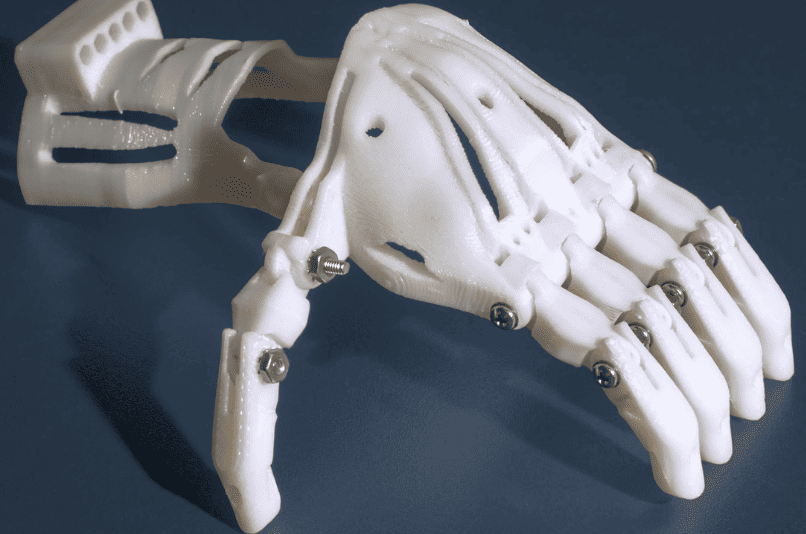

Print parts using engineering-grade materials to simulate mechanical performance under real-world conditions. Useful for testing strength, flexibility, and heat resistance — reducing risks before moving to production.

Build realistic product samples that users can touch, test, and interact with. Gather feedback on ergonomics, usability, and aesthetics to drive improvements ahead of final production runs.

Mimic the end-use product with high-resolution, near-production-quality prints. These samples are ideal for marketing previews, investor presentations, and internal approvals before committing to expensive tooling.

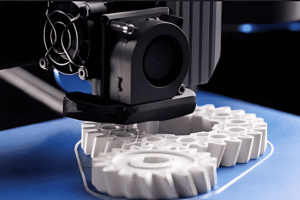

Create snap-fit parts, enclosures, or multi-part assemblies to validate interlocking mechanisms or stress points. These are vital for enclosure design, modular product development, and packaging solutions.

Faster Time-to-Market

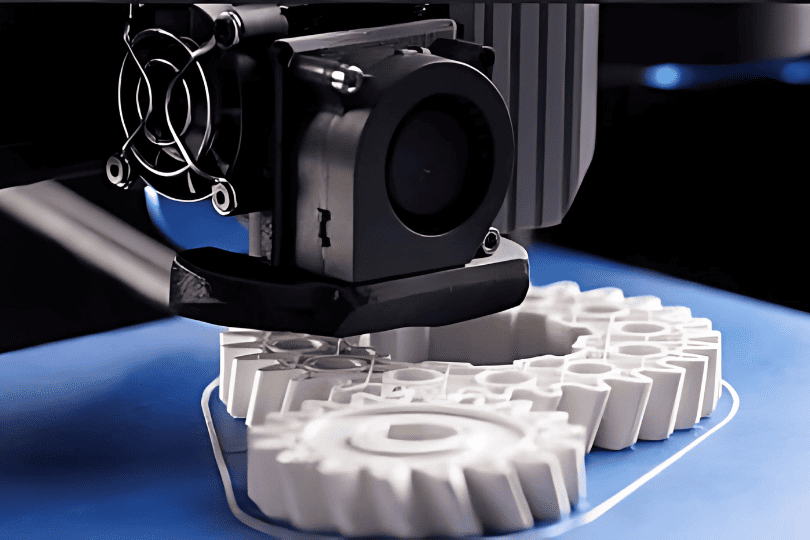

Cut product development timelines from weeks to days by quickly turning digital designs into physical prototypes.

Lower Iteration Costs

Eliminate the need for expensive tooling and produce multiple design iterations at minimal cost.

Wide Material Compatibility

Access a range of 3D printing materials such as PLA, ABS, PETG, TPU, Nylon, and engineering-grade composites for varied performance needs.

High Design Freedom

Create complex geometries, internal structures, and features that are impossible or cost-prohibitive using traditional manufacturing methods.

Short Lead Times

Parts can be printed and tested within hours, enabling rapid validation of design concepts and fast-paced R&D cycles.

Risk Reduction

Validate form, fit, and function before investing in expensive production tooling, reducing the chance of design errors.

Surface Finish

Printed parts may require post-processing such as sanding or coating to achieve injection-mold–like finishes.

Material Limitations

While versatile, not all 3D printing materials match the strength, thermal resistance, or compliance standards of molded plastics.

Build Volume Constraints

Large prototypes may need to be printed in parts and assembled, depending on the printer’s build area.

Dimensional Accuracy

Tolerance deviations can occur due to material shrinkage or printer calibration, especially for tight-fitting assemblies.

Post-Processing Time

Depending on the application, supports may need to be removed and parts finished, adding time and labor.

Not Always Ideal for Functional Testing

In some cases, prototype materials may not fully replicate the mechanical properties of final production materials.

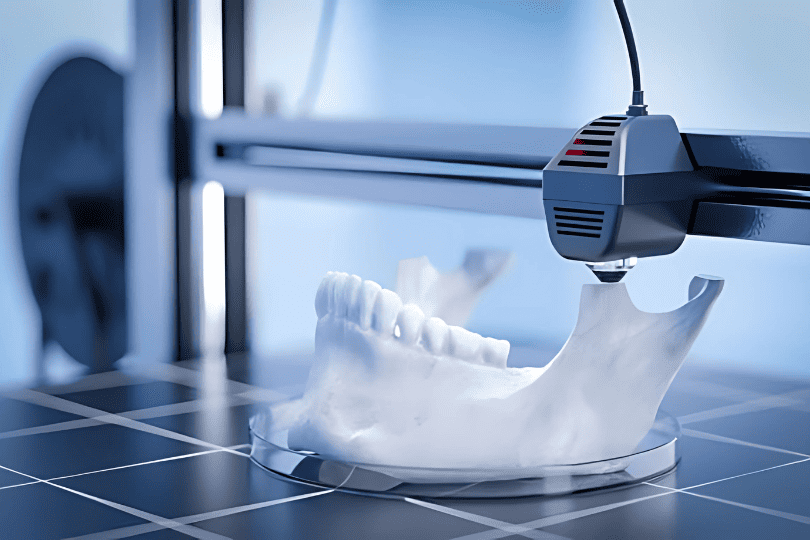

Used in the medical and dental fields to produce short-run parts and functional models with production-like quality.

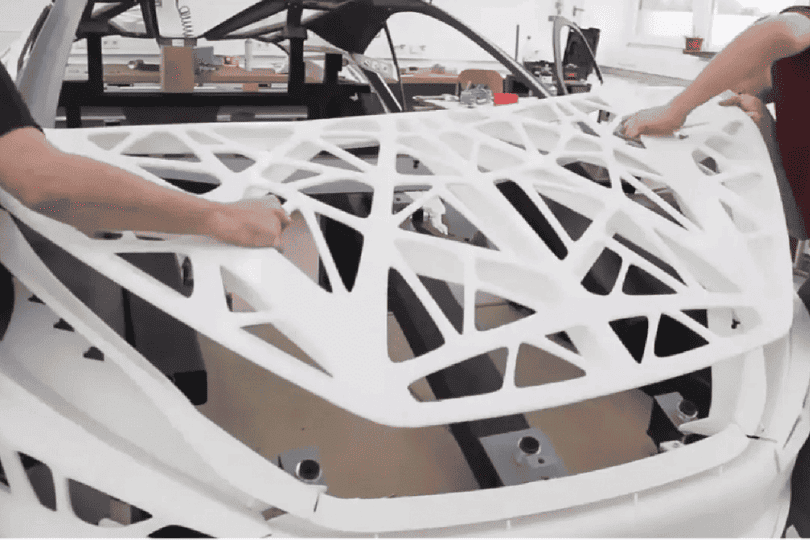

Used to create prototype parts, interior components, and test-fit parts with materials similar to production plastics.

Occasionally used for making multiple resin-based prototypes or molds for casting final pieces.

Widely used for low-volume production, testing market-ready prototypes, or replacing injection molding in early stages

Used for making durable props or costume components that need to replicate specific designs repeatedly.

Ideal for testing functional parts in small batches before committing to full-scale production.

© 2025 Fracktal Works Pvt. Ltd