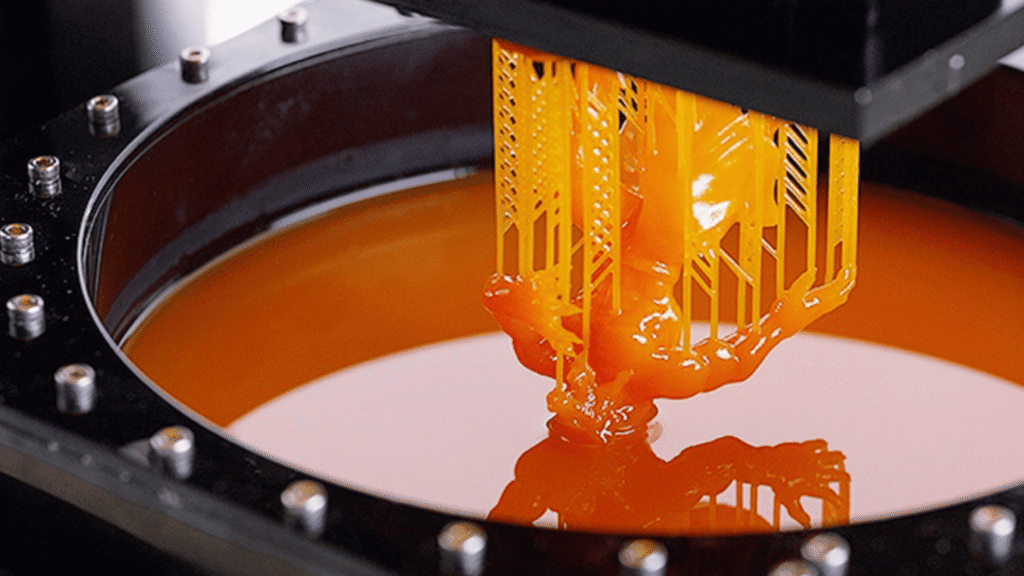

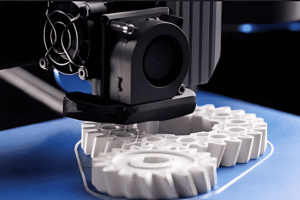

Stereolithography (SLA) is a 3D printing process that uses light to harden liquid resin into solid parts. It’s known for producing very smooth surfaces and highly detailed features.

SLA is a popular choice when you need high-quality, accurate parts—especially for projects and prototypes in design, healthcare, and product development.

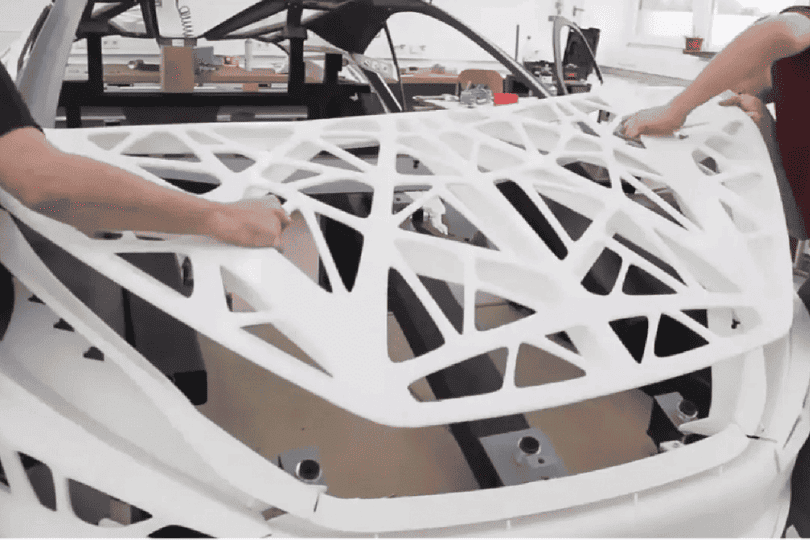

Ideal for producing prototypes with smooth surfaces and fine details. It’s often used in product development to test design aesthetics, fit, and form before moving into production.

Used to produce master patterns for silicone molding or casting. These high-detail prints are perfect for creating accurate and clean molds in processes like vacuum casting.

SLA materials can simulate glass-like transparency, making it suitable for printing microfluidic devices, optical parts, or models that need visual clarity.

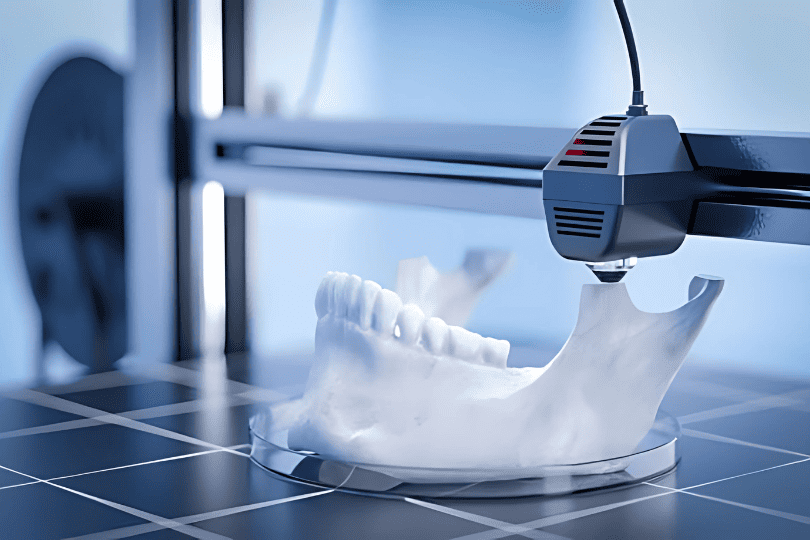

Valued in healthcare for producing precise dental tools and patient-specific anatomical models, improving treatment planning and outcomes. Their accuracy and material versatility make them ideal for various medical and dental applications.

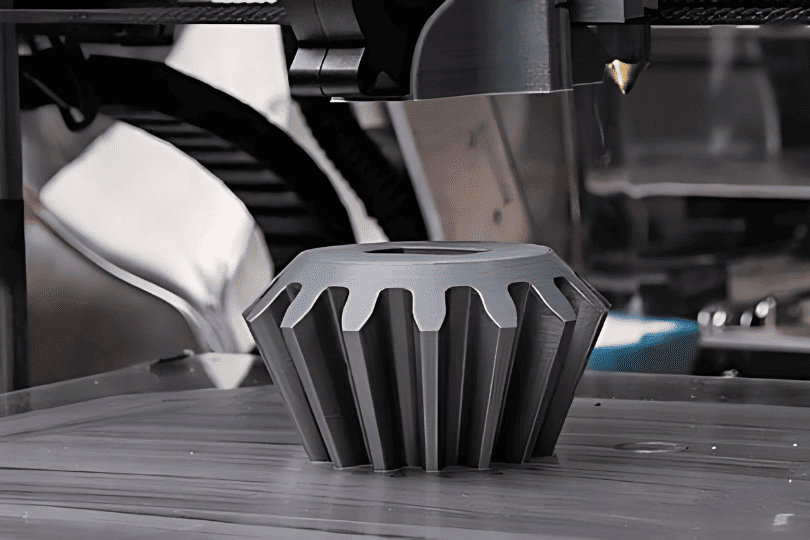

Ideal for producing jigs, fixtures, and custom tools tailored to specific manufacturing needs. These components can be quickly designed, printed, and deployed to improve efficiency on the production line.

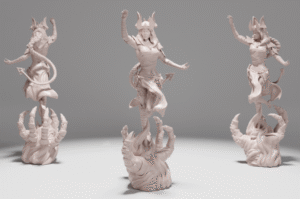

Produce detailed figurines, miniatures, and sculptures. SLA’s ability to reproduce complex geometries makes it a go-to tool for visual artists, model makers, and hobbyists.

High Resolution & Detail

Offers excellent precision and fine detail, ideal for intricate designs like dental models, jewelry, and miniatures.

Smooth Surface Finish

Parts come out with a smooth surface, often needing minimal post-processing compared to FDM prints.

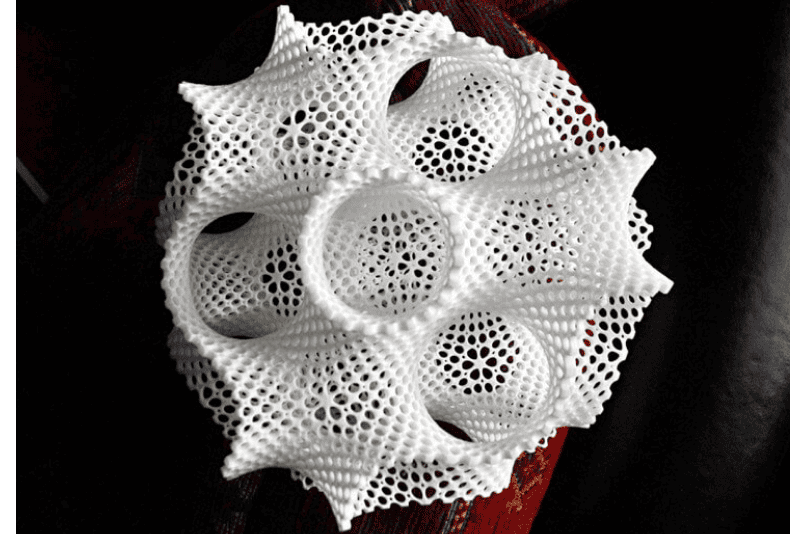

Complex Geometry Capability

SLA handles complex shapes and internal structures better than many other 3D printing technologies.

Material Variety (Resins)

A wide range of photopolymer resins is available, including flexible, tough, castable, and biocompatible options.

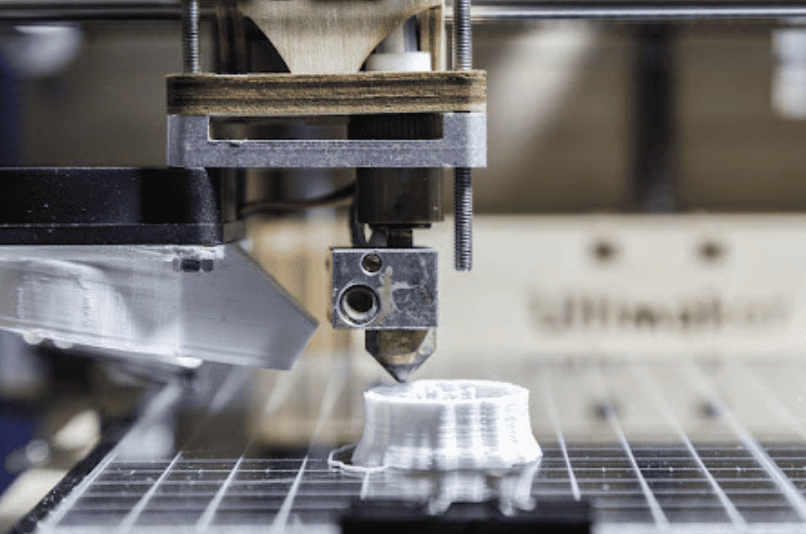

Less Visible Layer Lines

Layer lines are much less noticeable compared to FDM, giving parts a professional look.

Tight Tolerances

SLA is great for applications requiring dimensional accuracy, such as prototyping or engineering models.

Limited Build Size

SLA printers typically have smaller build volumes compared to FDM machines.

Material Handling Hazards

Resins are toxic in liquid form, requiring gloves, eye protection, and proper ventilation.

Slower Print Speed for Large Models

While high-resolution prints are possible, they can take a long time to complete, especially for tall objects.

Higher Material Cost

Resin is generally more expensive than FDM filament, and wastage can add up.

Post-processing needed

Prints must be washed (usually in isopropyl alcohol) and cured with UV light after printing.

Printer Maintenance

The resin tank and build platform require regular cleaning and occasional replacement.

Used in classrooms and labs to teach 3D printing principles and produce high-detail prototypes for student projects.

Applied in creating design prototypes, small components, and visual models for concept testing.

Used to create highly detailed master patterns for casting custom jewellery pieces.

Used to create master patterns for molds or jigs and fixtures for assembly lines where visual fidelity is needed.

Create accurate, detailed models and tools such as surgical guides, dental molds, and anatomical parts.

Suitable for concept models, design validation, and fit-testing parts where visual detail is critical.

Used to create detailed props, miniatures, and costume elements thanks to its ability to capture intricate details.