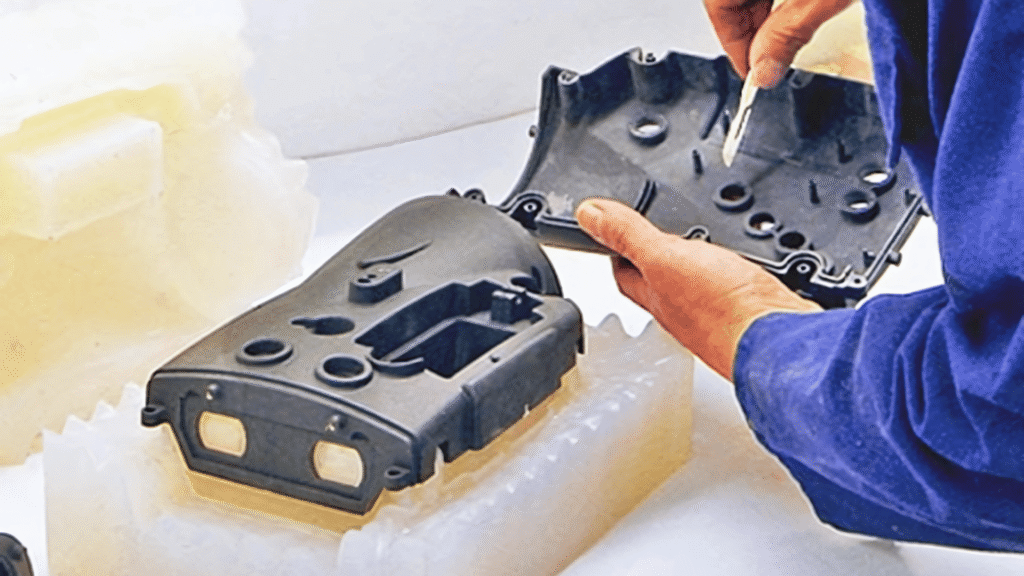

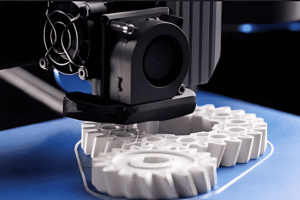

Vacuum casting uses silicone molds to make precise copies of a part, usually starting from a 3D printed model. This process is quick, affordable, and works with a variety of materials—perfect for creating high-quality parts.

It’s great for producing small batches of parts, testing designs, or making product samples in industries like automotive, consumer goods, and healthcare.

Ideal for producing small batches of high-quality plastic parts. It bridges the gap between prototyping and mass production, offering a cost-effective alternative to injection molding.

Vacuum casting helps create prototypes from materials that mimic final-use plastics. These parts are tested for fit, performance, and durability in real-world applications.

Make product samples for user testing or marketing feedback. It helps validate the design, look, and feel before committing to full-scale manufacturing.

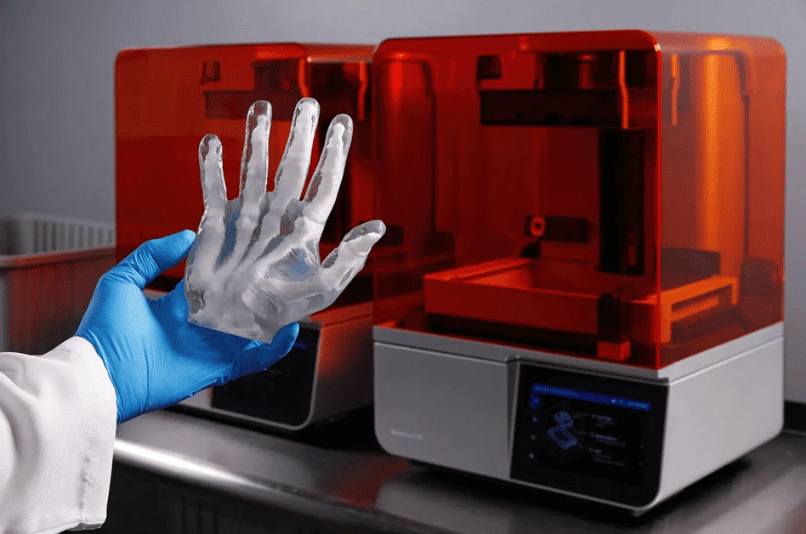

Used to produce enclosures for medical devices, especially during pre-market testing or when only limited quantities are needed for trials or evaluation.

Used to replicate dashboard components, clips, and housings, allowing for fit and function testing before final tooling.

Used to produce prototype packaging components—like lids, containers, or inserts—with final-product materials and appearance for testing and marketing purposes.

High-Quality Surface Finish

Produces smooth, detailed surfaces that often require little or no post-processing.

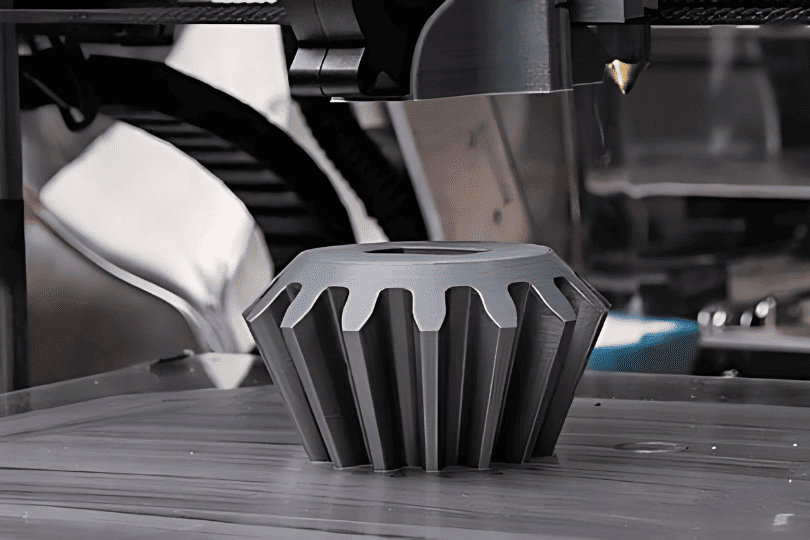

Excellent Detail Reproduction

Accurately replicates the master model, capturing fine features and textures.

Wide Range of Materials

Supports various polyurethane resins that mimic the properties of ABS, rubber, PP, etc.

Short Lead Times

Faster than injection molding for small batches, especially in prototyping or pre-production.

Low Tooling Costs

Silicone molds are cheaper and quicker to produce than metal molds used in injection molding.

Color and Transparency Options

Allows for pigmented, clear, or tinted parts without secondary finishing.

Limited Mold Life

Silicone molds typically last for only 15–25 parts, depending on complexity and resin type.

Size Limitations

Not ideal for very large parts due to mold and chamber size restrictions.

Manual Labor Intensive

Requires skilled technicians for mold creation, casting, and finishing—limiting scalability.

Material Limitations

Limited to polyurethane-based materials, which may not meet all engineering or regulatory standards.

Shrinkage and Warping

Parts may shrink or deform slightly during curing, especially if the mold isn’t properly designed.

Not for Mass Production

Unsuitable for high-volume manufacturing due to mold wear and slower production speed compared to injection molding.

Used in the medical and dental fields to produce short-run parts and functional models with production-like quality.

Used to create prototype parts, interior components, and test-fit parts with materials similar to production plastics.

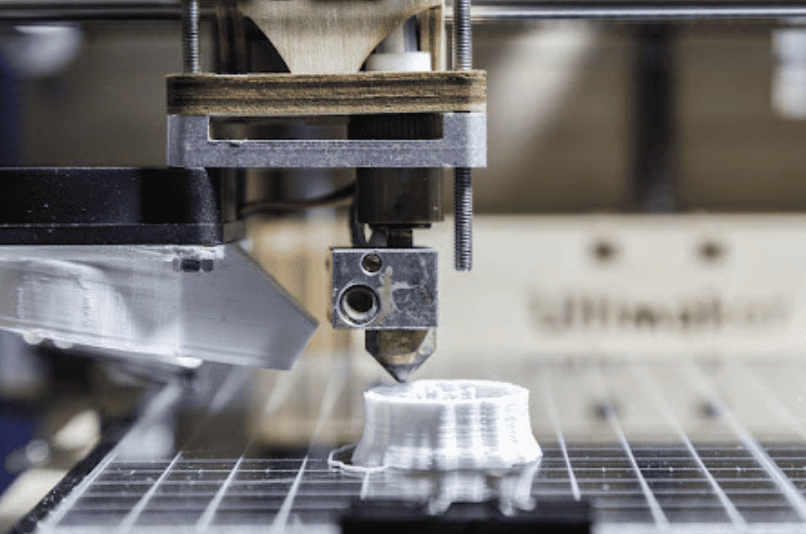

Occasionally used for making multiple resin-based prototypes or molds for casting final pieces.

Widely used for low-volume production, testing market-ready prototypes, or replacing injection molding in early stages

Used for making durable props or costume components that need to replicate specific designs repeatedly.

Ideal for testing functional parts in small batches before committing to full-scale production.