Ever wondered how a stunning architectural vision on a computer screen becomes a real-world building you can walk through? For generations, that journey was long, expensive, and often full of compromises.

But now, a groundbreaking technology is shattering old limitations and changing the game for architects, builders, and clients alike: 3D printing.

Is architecture on the brink of a giant leap forward? The answer is a resounding yes.

Let’s explore how this incredible innovation is taking us from tiny-scale models to full-sized, livable homes.

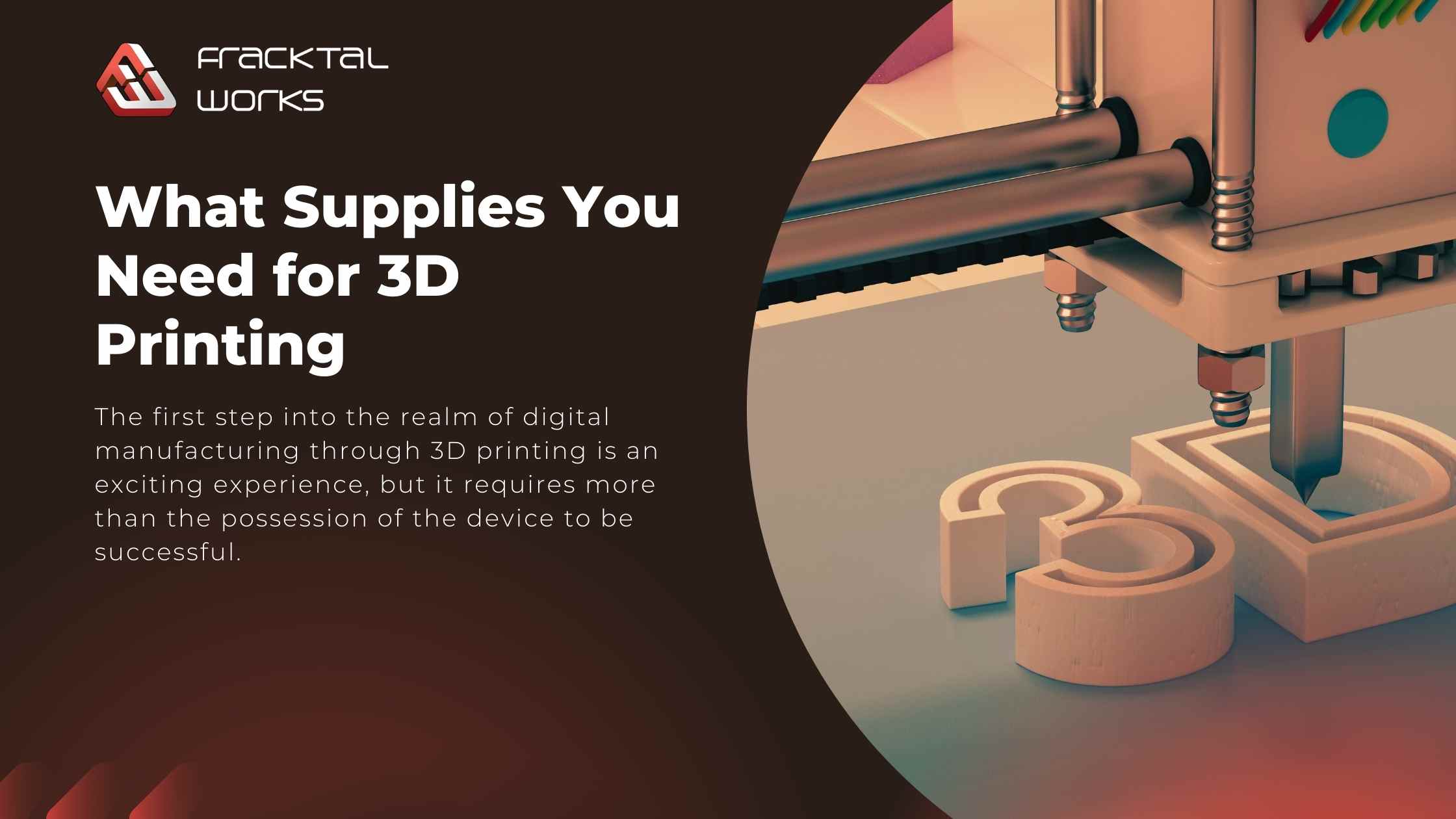

Beyond Cardboard and Glue: The New Age of Architectural Models

For decades, bringing an architectural vision to life for a client meant one thing: painstaking manual labor. Skilled craftspeople would spend weeks building intricate scaled models from wood, foam, or cardboard. This process was not only slow and expensive but also made it incredibly difficult to make quick changes or accurately represent complex, modern designs.

3D printing has completely transformed this crucial first step. An architect can now design a detailed 3D model on a computer and, within hours or days, have a perfectly precise physical prototype in their hands.

Here’s why it’s a game-changer:

- Speed and Efficiency: A model that once took weeks to build can now be printed in a fraction of the time.

- Unmatched Precision: Intricate details and complex geometric shapes that are nearly impossible to create by hand can be printed with flawless accuracy.

- Effortless Revisions: If a client wants a change, the digital file can be tweaked and a new version printed quickly and cheaply. No more starting from scratch!

- Cost-Effective: By reducing manual labor and material waste (you only use what you need), 3D printing makes prototyping more affordable. It even opens the door to using innovative recycled materials.

More Than Just Models: Printing Livable Homes

The true revolution, however, is in scaling up. The same technology used for detailed models is now being used to construct entire buildings. Imagine a giant robotic arm moving across a foundation, extruding layers of a special concrete mix to build the walls of a house from the ground up. It’s not science fiction—it’s happening right now.

While things like windows, doors, and plumbing are still installed manually, the core structure of a home can be printed in a matter of days, not months. This approach offers incredible benefits for the construction industry.

- Drastically Faster Construction: Crews have successfully printed the basic structure of a small home in as little as 24 hours.

- Reduced Costs: Fewer labor hours and highly efficient material usage can lead to significant savings, potentially making housing more affordable.

- Creative Freedom: Architects can design unique, curved walls and innovative structures that would be incredibly expensive or difficult to build with traditional methods.

- Increased Safety and Less Waste: Automating the heavy lifting reduces on-site accidents and minimizes the environmental footprint of a construction project.

What’s Next? Building on Earth and Beyond

3D printing in construction is no longer a niche experiment; its global market is on track to be worth billions. As the technology evolves, we’ll see printers capable of building multi-story structures, integrating reinforcements, and even printing floors.

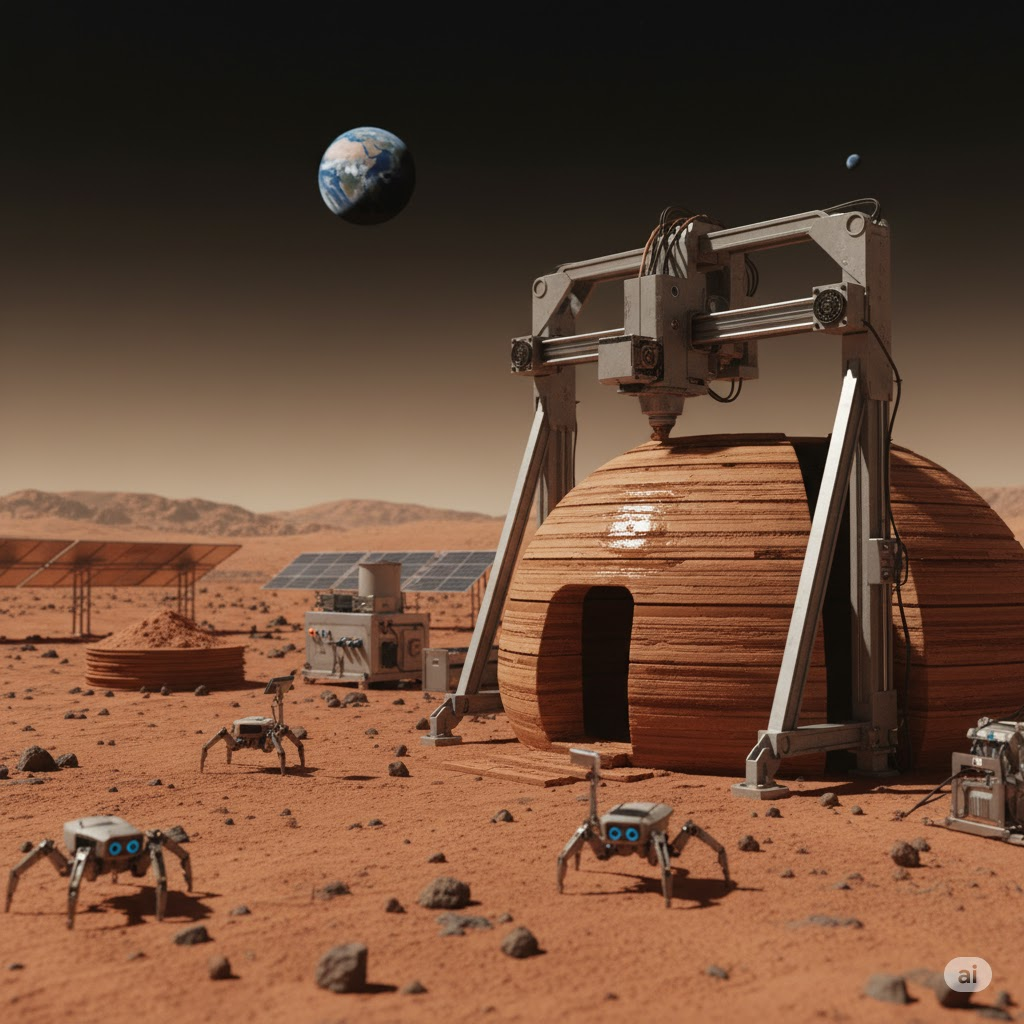

The future potential is truly staggering. By combining 3D printing with AI and robotics, we’re looking at a future where we could construct buildings on the Moon or Mars without ever sending a construction crew. Automated printers could use local materials to build habitats, paving the way for off-world exploration.

A Revolution in Concrete and Code

3D printing has moved from a rapid prototyping tool to a revolutionary manufacturing force in architecture. It’s a paradigm shift that benefits everyone involved, from the architect with a bold vision to the client who gets a better, more affordable final product.

This state-of-the-art technology is here to stay, making the process of designing and building our world faster, cheaper, and with more creative freedom than ever before. It’s not just about building differently; it’s about building smarter.