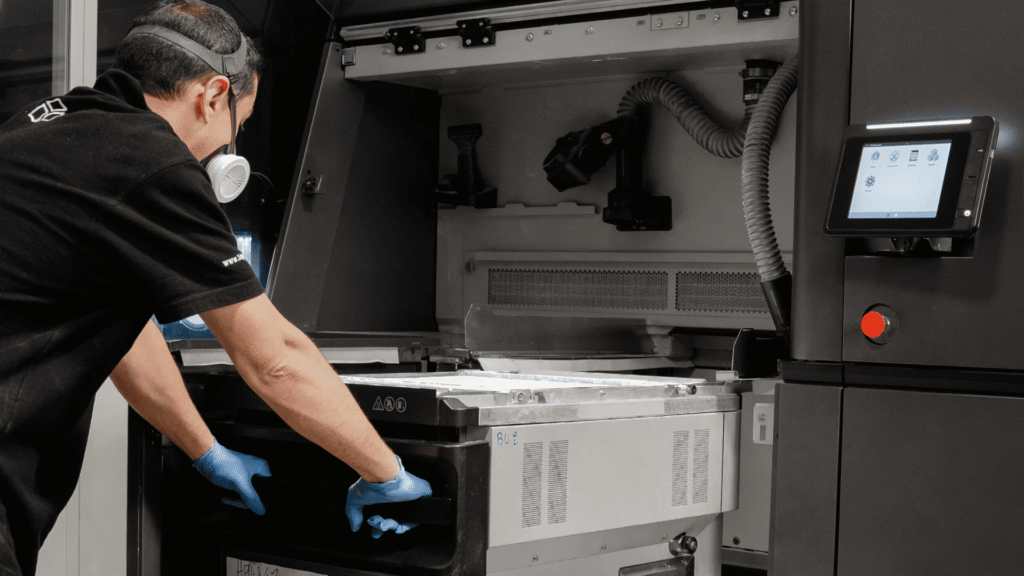

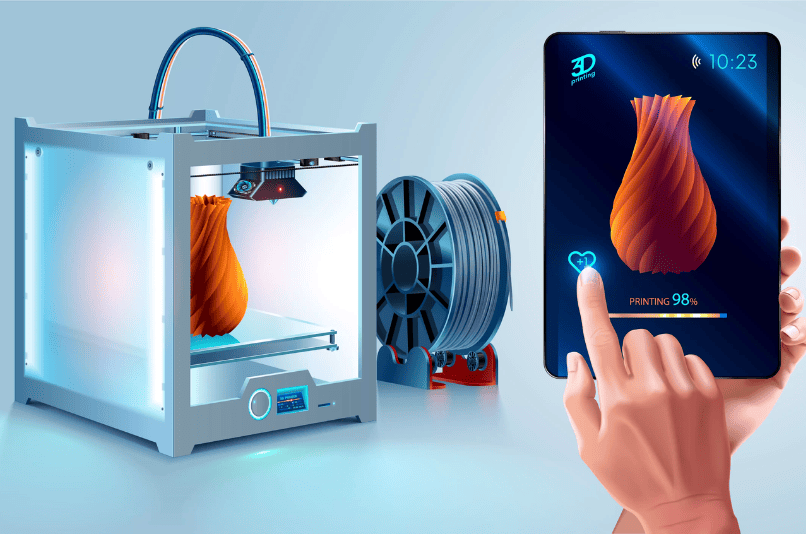

HP Multi Jet Fusion (MJF) creates parts by jetting fusing agents onto a powder bed and applying energy to fuse the material layer by layer. This advanced technology is known for producing strong, detailed, and functional parts quickly and efficiently.

MJF is ideal for both prototyping and production, especially when precision and speed are critical. It has excellent surface finish, dimensional accuracy, and mechanical properties.

Rapidly testing designs before mass production through form, fit, and function prototypes with iterative validation. It enables functional testing under real conditions, accelerating product rollout.

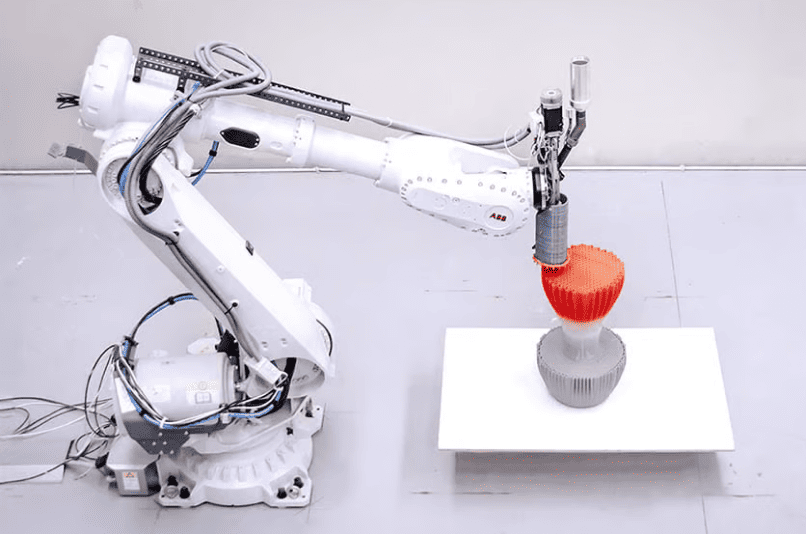

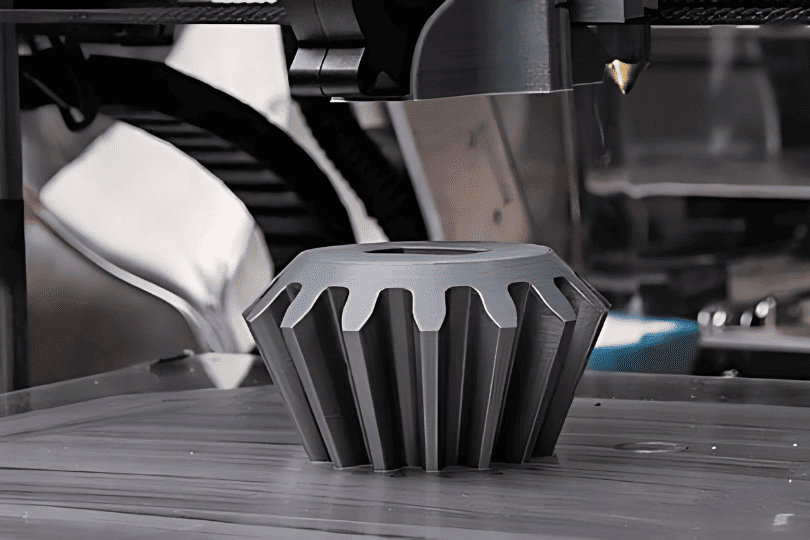

HP MJF 3D printing offers a powerful solution for producing strong, lightweight, and design-flexible components. It is ideal for sensor mounts, robot chassis, drone arms, and cable systems with rapid prototyping benefits.

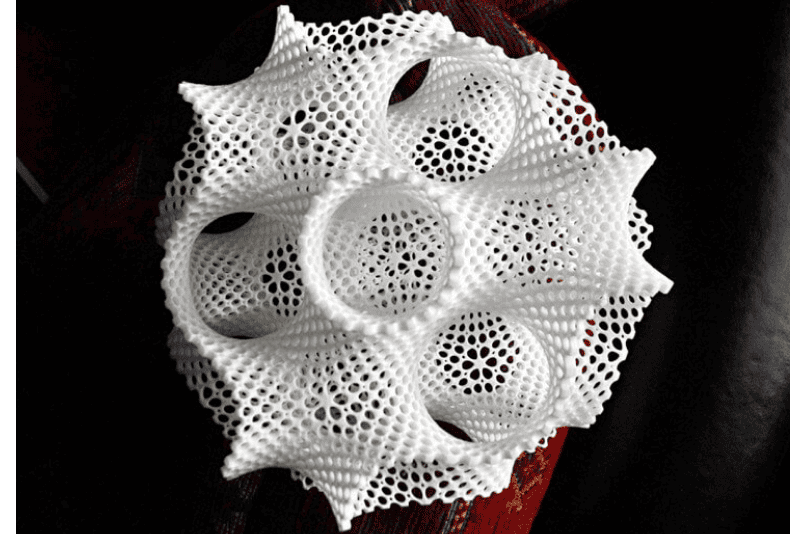

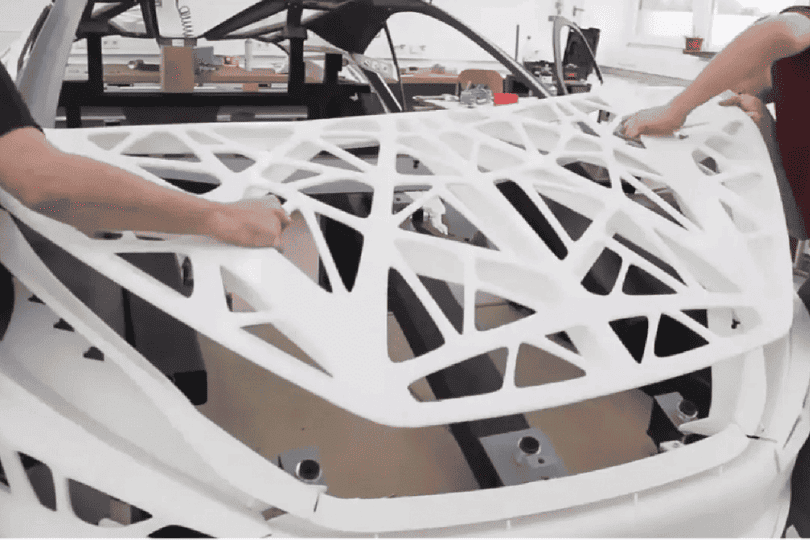

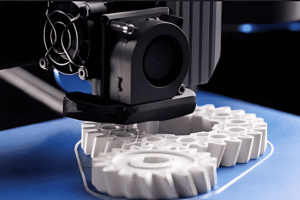

Complex geometries can be printed as single, functional units without assembly. Enables design freedom beyond traditional methods, allowing lightweight lattice structures, internal channels, and interlocking moving parts.

Perfect for on-demand, short-run production without the need for costly tooling, making it ideal for custom, replacement, or small-batch parts. It enables flexible, cost-effective manufacturing for individual needs.

Before mass production, MJF enables testing parts under real-world stresses, including snap-fit assemblies, moving mechanisms, and waterproof casings. It ensures thermal and chemical resistance.

Use MJF to digitally store and print parts on demand, reducing the need for warehousing. This allows fast production of spare, legacy, and emergency parts with quick iteration during upgrades.

Fast Print Speeds

Faster than many other 3D printing technologies, especially for production-level quantities.

Excellent Mechanical Properties

Parts produced are strong, isotropic, and suitable for functional prototyping and end-use applications.

High Detail and Accuracy

MJF offers fine feature resolution and sharp edges, suitable for complex, detailed parts.

No Need for Support Structures

Powder acts as its own support, allowing more freedom in design and fewer post-processing steps.

Efficient Batch Production

Entire print beds can be packed with parts, making it very cost-effective for short-run manufacturing.

Good Surface Finish

Parts have a uniform, smooth matte finish that’s often better than SLS.

High Initial Cost

MJF machines are expensive, typically geared toward industrial and enterprise use.

Limited Material Selection

While growing, material choices (mostly nylon-based) are still relatively limited compared to other processes.

Post-Processing Required

Parts must be cleaned of powder and may require dyeing or smoothing for aesthetic applications.

Large Footprint

MJF systems require substantial space and often come with multiple units (printer, build unit, processing station).

Not Ideal for Very Fine or Transparent Parts

MJF doesn’t match SLA’s detail or ability to print clear/translucent parts.

Powder Handling and Waste

Although some powder can be reused, the process generates unused powder that must be managed or recycled.

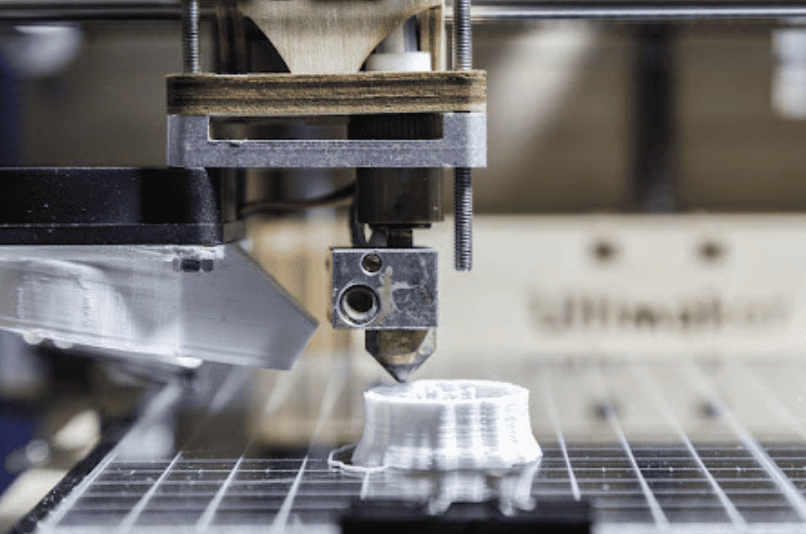

Used in universities and research labs for teaching and hands-on prototyping. It allows students and researchers to quickly iterate and visualize complex designs.

Used for rapid prototyping and producing end-use parts. MJF delivers functional, heat-resistant parts with strong mechanical properties.

Mainly used for prototyping, for high-detail prints that can be used to test designs or create molds for final metal casting.

Used for low-volume production, custom fixtures, tooling, and jigs, reducing lead time and costs while maintaining part strength compared to traditional manufacturing.

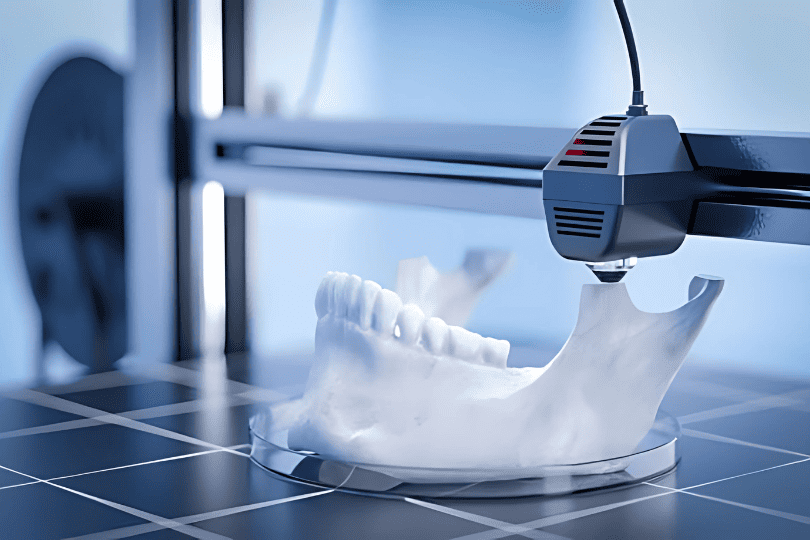

For creating customized prosthetics, orthotics, and dental models with high precision and strength.

Ideal for rapid prototyping and functional testing, enabling engineers to validate designs, test mechanical performance, and produce fit-for-use end parts.

Used to produce props, costumes, and prototypes for animation or film. The high resolution and surface detail are great for visual quality and customization.

Used for creating customized equipment components and patient-specific devices. Its fast, durable printing is especially valuable in healthcare innovation.