Selective Laser Sintering (SLS) creates parts by sintering powdered thermoplastic materials using a high-powered laser. It is ideal for both prototyping and low-volume production, to create detailed and complex geometries.

SLS is a go-to solution for engineering, medical, and industrial applications where performance and durability matter. It delivers exceptional strength, surface finish, and accuracy.

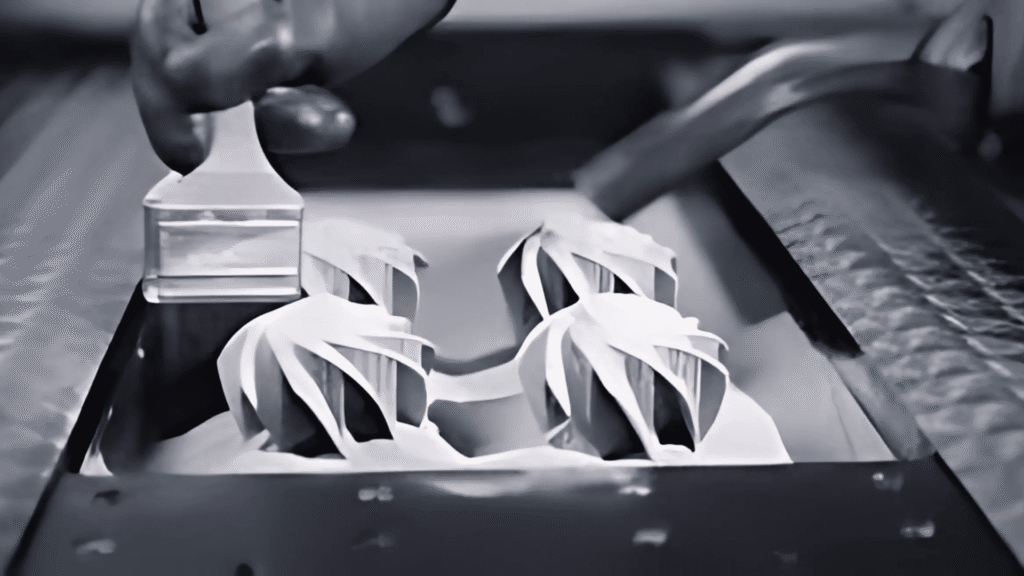

Quickly create high-resolution, complex prototypes with SLS, enabling faster iterations while eliminating support structures and minimizing post-processing waste.

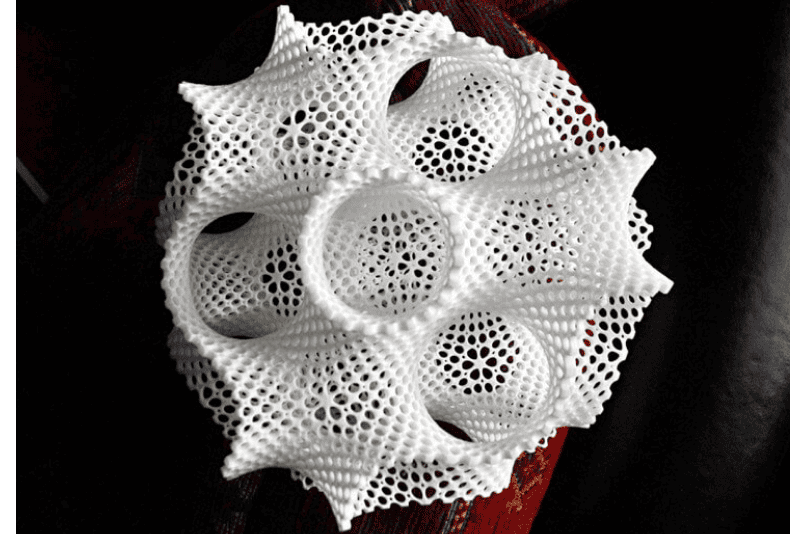

Leverage the design freedom of SLS to create strong, lightweight parts with internal lattice structures.

Produce durable, heat- and wear-resistant jigs, fixtures, and tooling components quickly and cost-effectively.

Produce durable, high-precision, end-use parts for aerospace, automotive, and medical applications with excellent performance and efficiency.

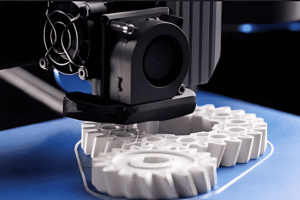

Reduce the number of parts in an assembly by printing intricate, interlocking geometries as a single piece—minimizing assembly time, errors, and maintenance.

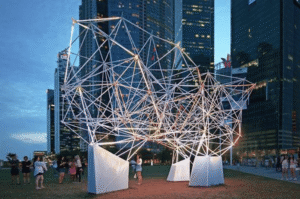

Used in universities and labs to create functional teaching aids, research tools, and experimental components. Artists and designers also use SLS for intricate, customized fashion accessories, sculptures, and wearable art.

No Support Structures Needed

The surrounding powder supports the part during printing, allowing for highly complex geometries.

Strong and Functional Parts

SLS produces durable parts suitable for functional testing and end-use applications.

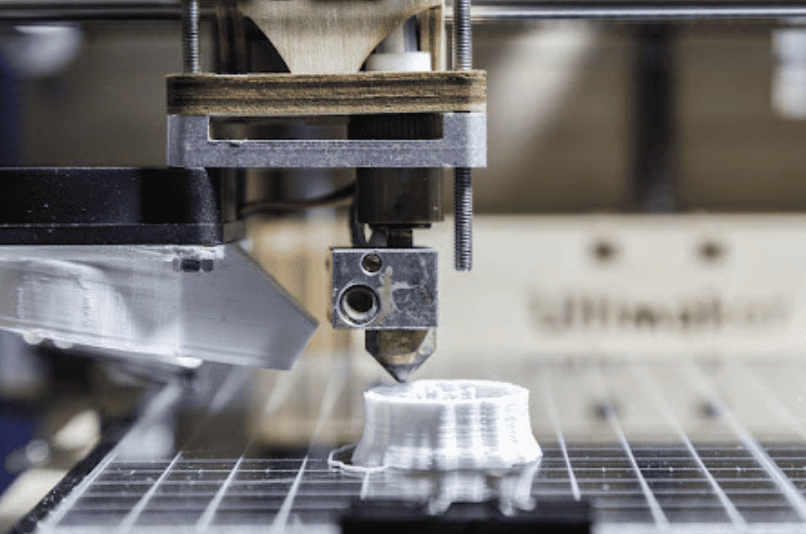

Rapid Prototyping

Produces strong, detailed prototypes similar to injection-molded parts for fast design iteration.

Good Mechanical Properties

SLS parts are isotropic (uniform strength in all directions), unlike many other 3D printing types.

Efficient Use of Material

Unfused powder can often be reused, reducing waste and material costs.

Ideal for Batch Production

Multiple parts can be nested in one build, making it cost-effective for short production runs.

Rough Surface Finish

SLS prints tend to have a grainy surface texture, often requiring post-processing.

High Equipment Cost

More expensive and complex compared to FDM or SLA machines.

Post-Processing Needed

Parts must be cooled, depowdered, and often finished (dyed, polished) after printing.

Powder Handling Risks

Fine powders require careful handling, ventilation, and protective equipment.

Slow Cooling Times

Parts must cool down inside the machine to avoid warping, increasing the total turnaround time.

Limited Material Colors

Most SLS prints are in white or grey nylon; vibrant colors typically require post-processing.

It is used in universities and labs to produce prototypes, teaching aids, and experimental tools for hands-on learning.

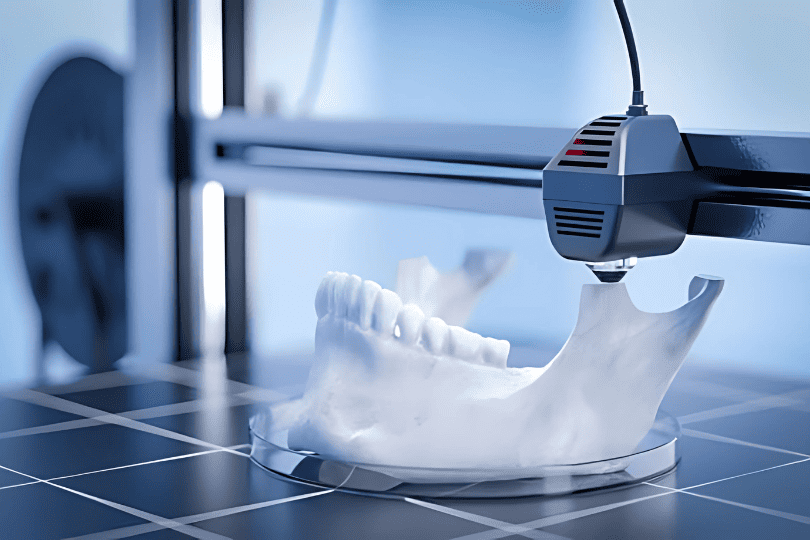

For creating custom implants, prosthetics, dental crowns, and surgical guides with high precision.

To craft intricate, detailed designs and customized pieces that are difficult to make with traditional methods.

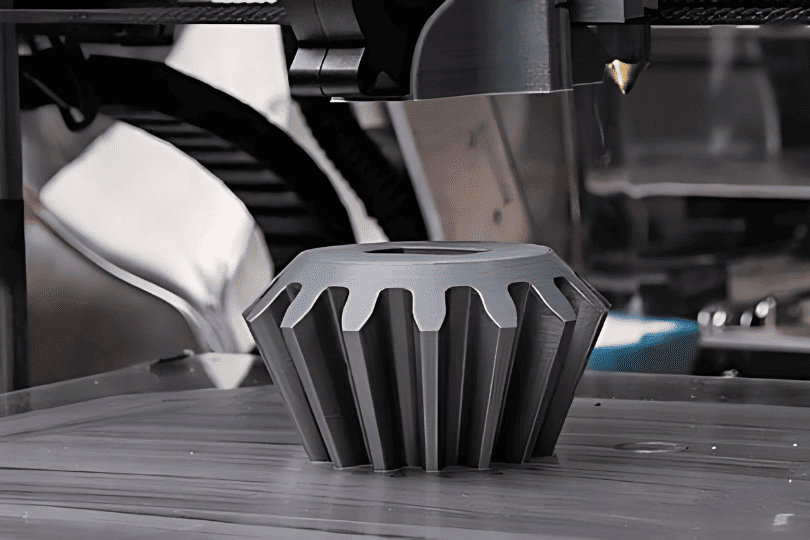

It enables production of functional, durable parts and prototypes with complex geometries, making it ideal for small-batch production and custom components.

To produce specialized equipment parts and customized devices efficiently.

For rapid prototyping, functional parts, and complex components that require durability and detail.