Introduction

The first step into the realm of digital manufacturing through 3D printing is an exciting experience, but it requires more than the possession of the device to be successful. Producing consistent quality requires a suite of supplies and accessories for smooth usage, precise printing, and simple maintenance. At Fracktal Works, we provide you with these essentials to ensure a seamless and trustworthy 3D printing experience. Here, we show you the must-have supplies for 3D printing, why they are important, and how to work with them. We’ll also point out Fracktal Works Print Stick™, a hassle-free but potent solution that addresses one of the most prevalent issues in 3D printing: bed adhesion.

Essential Supplies for 3D Printing

PTFE Tube

The PTFE tube is an important connection in the filament route, directing material from the spool to the extruder. A high-quality tube minimizes friction and provides smooth feeding, particularly in Bowden-style printers where the travel is longer. With time, PTFE tubes can weaken due to heat degradation, causing extrusion problems. Changing the tube at regular intervals ensures smooth, jam-free printing.

Build Plate

All prints start at the build plate, and how well the surface quality is from there directly affects adhesion, dimensional quality, and end results. A level, stable build plate prevents warping and allows the first layer to bond properly. Dust and residue are cleaned out by regular cleaning. If the plate is uneven or damaged, it will result in failed prints, so its condition must be watched.

Nippers

Filament preparation is a minor but important step, and nippers simplify the process. They provide clean, sharp cuts when adding new filament to prevent clogging. Nippers can also be used after printing to remove supports and tidy up edges. Worn-out or dull nippers can crush filament rather than cut it, so they should be replaced when they become blunt.

Allen Keys

Allen keys, or hex wrenches, are a must-have for the maintenance of 3D printers. From tightening bolts to belt adjustments, these handy tools keep your printer mechanically sound. The wrong size can strip screws, making adjustments impossible. A trusty set of properly sized keys helps keep your printer in the best working order.

Spool Holder

A spool holder may appear simple, but it is important in uninterrupted printing. It permits filament to feed consistently without tangling and introducing unnecessary tension. A weak or unbalanced holder can cause irregular extrusion or worse, a spool falling in the middle of a print that takes many hours. Investing in a reliable holder ensures smooth filament flow and reduces downtime.

Nozzle Cleaner

With time, residue may accumulate in the nozzle and lead to clogging. A cleaner for the nozzle maintains extrusion on a steady basis and prolongs the life of the nozzle. Gradual, low-pressure cleaning avoids under-extrusion as well as surface blemishes. The most important aspect is to use the cleaner sparingly; excessive force can damage the nozzle tip.

Cleaner for the nozzle

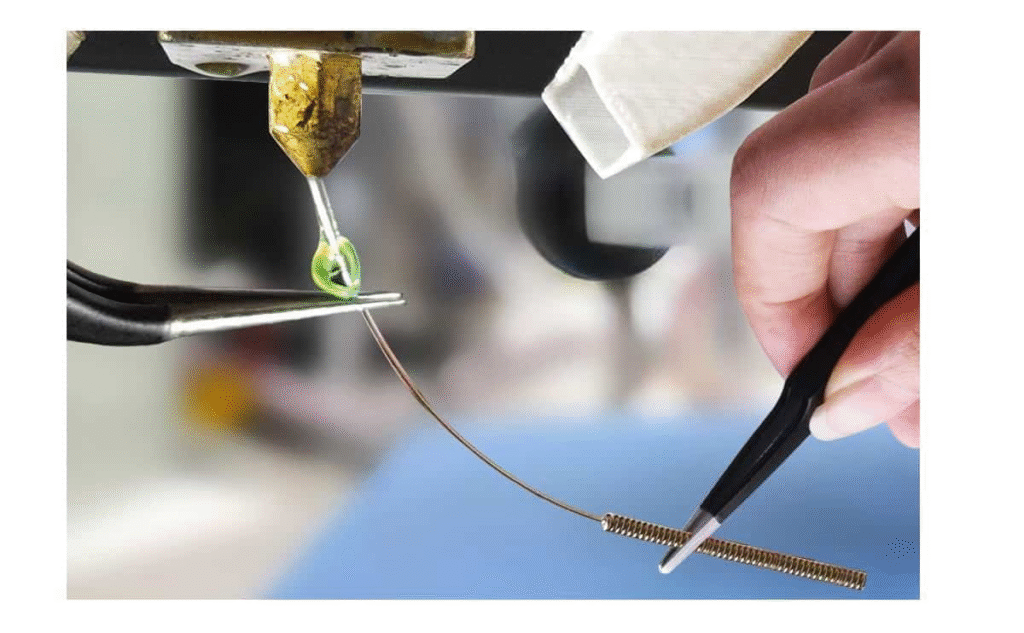

Tweezers

Tweezers are a small but vital accessory in any 3D printing toolkit. They make it easy to remove stray strings of filament, clean the nozzle area, or pick up delicate printed parts without burns. They are also useful for handling small details that are difficult to manage by hand, keeping your workflow safe and precise.

USB Drive

The movement of cut files to your printer is typically carried out through a USB drive. Although it does not necessarily look as vital as other equipment, a good drive will help keep your print files intact and error-free. Foul files result in printing failures, so it is best to use quality drives and never fail to eject after use.

Power Cable

A good power connection is vital for lengthy prints that last for hours or days. A well-insulated, secure power cord keeps a job going without abrupt shutdowns or sag that will destroy a work in process. Inspecting cables for damage or wear is an easy, efficient means of eliminating unnecessary failures.

WD-40 Degreaser

As with any machine, a 3D printer needs to be maintained, and a WD-40 degreaser is used to keep moving parts clean. It eliminates dust, grease, and residue that would otherwise accumulate and interfere with performance. The best approach is to spray the degreaser onto a cloth prior to applying it to the machine, avoiding sensitive electronics.

Print Adhesion Made Easy with Fracktal Works Print Stick

Perhaps the most frequent 3D printing frustration is bad bed adhesion. If the initial layer doesn’t adhere well to the build plate, prints will warp, peel off, or simply fail. That’s where Fracktal Works Print Stick™ steps in and provides an easy yet effective answer. Specifically formulated for 3D printing, it has strong adhesion on a broad spectrum of materials such as PLA, ABS, PETG, and Nylon. Compared to old school tapes or adhesives, it washes off with just water and will not leave any residue, which also helps prolong the life of your build plate. Portable and small, Fracktal Works Print Stick™ is convenient to take along and apply wherever necessary. For optimal results, apply it evenly to the build surface and keep it well-sealed to avoid drying. With Fracktal Works Print Stick, available from Fracktal.in/printstick, you can print assured that your first layer will remain stuck in position.

Other Recommended Supplies for 3D Printing

In addition to the typical accessories, some more supplies are available that simplify and make 3D printing more consistent. Material storage mediums, like dry boxes or sealed containers, are necessary for preserving materials effectively. Safety equipment like heat-resistant gloves and proper ventilation provides a safer print environment. Precision tools such as digital calipers are priceless for measuring filament diameter and ensuring print quality. It is also a good idea to have spare nozzles and hotend components readily available, as these parts will eventually wear out with regular use, particularly with abrasive materials. Lastly, cleaning scrapers and brushes simplify regular maintenance by enabling you to clean residue from the nozzle and detach prints safely from the build plate.

Safety equipment like heat-resistant gloves.

In summary

3D printing is a very gratifying process, yet it takes the proper set of supplies and tools to deliver successful results consistently. From simple items such as build plates, PTFE tubes, and nippers to upkeep necessities like degreasers, tweezers, and nozzle cleaners, every accessory contributes to the workflow. Trustworthy USB drives and power cables provide another level of reliability, while spool holders ensure continuous prints without interference. For most users, the largest difference-maker is being able to discover an adhesive solution that gets the job done, and that’s what Fracktal Works Print Stick™ provides with its reliable, mess-free formula. Here at Fracktal Works, we want to ensure that every print begins and ends right. With proper supplies, you can break free from experimentation and really experience the creativity and accuracy that 3D printing has to offer.